At

the conclusion of Part 13 of this blog, we took the "mostly completed"

rig to Baja with some of the local moggers. We had a great time

and the truck performed as expected. There were no problems with

any of the additions that we installed prior to the trip. You can

see photos of the Baja trip by clickking here.

Once we got back into the U.S. and the dust and mud was cleaned from the vehicle, we continued prosecuting our set of actions for the truck. The photos below show what we did as part of these actions.

I

did not take a bunch of "work in progress" photo, but the photo above

shows the finished product. The objective was to provide a

convenient and robust way to store and mount our flat panel display for

travel and use. We fabricated a frame that allows the panel to be

folded up for travel and then rotated down for use. The top tray

provides a spot to put the laptop and hard drives that store the

movies. The mount does not interfere with the movement of the top

and still provided optimum viewing height.

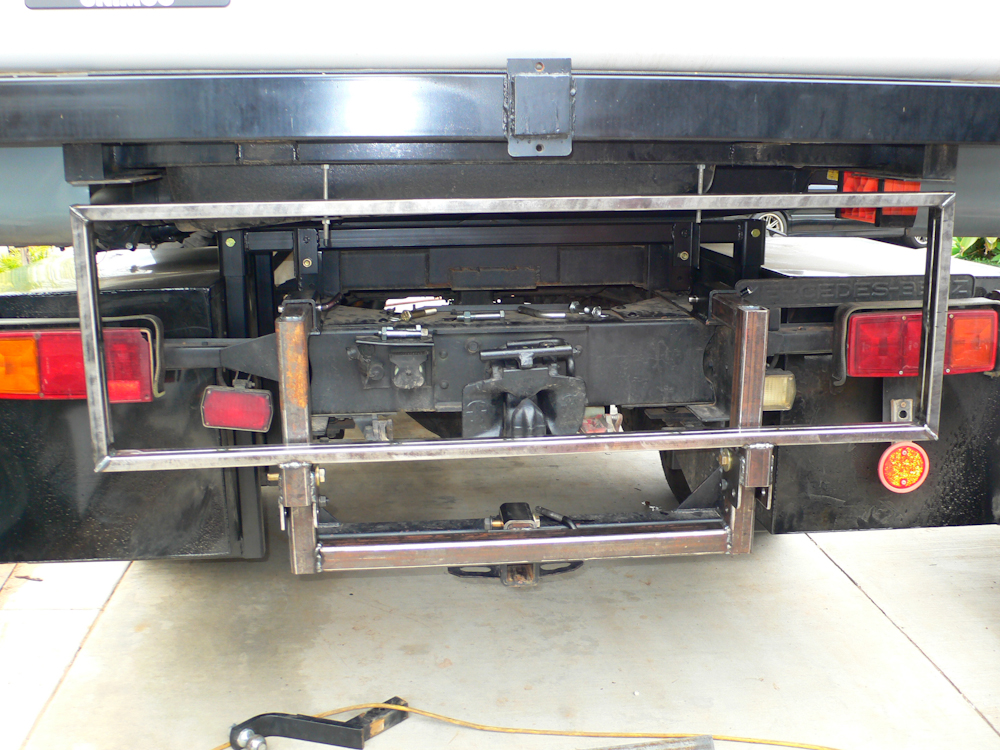

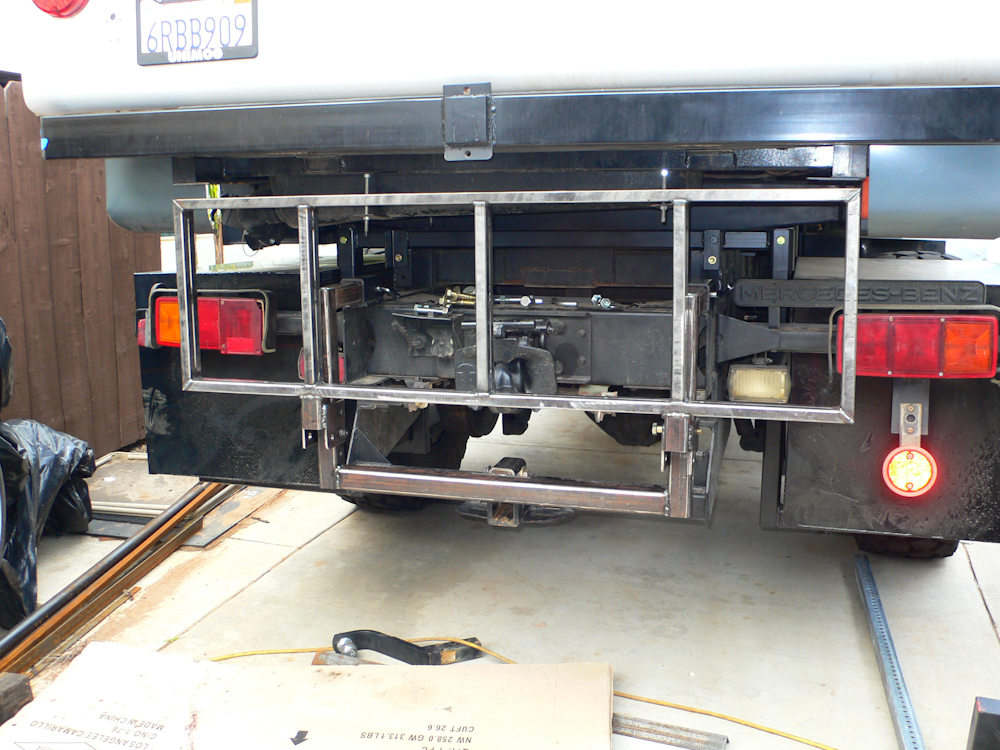

From

the LCD mount, we moved on to completion of the cargo box mounts for

the rear of the truck. Like the other mounts, these will be

constructed of 2x2 1/4" wall square tubing. The completed

assembly will plug into trailer hitch reciever to allow the assembly to

be removed if required. Above, you can see the reciever mount has

been cut, drilled and tapped in preparation for welding. Also

note that the 1/4 wall tube has been chamfered to insure full

penetration of the welds for strength.

Once

the mounting bars were fabricated, they were test installed to confirm

measurements of the balance of the components. The rear bar is

attached to a cap plate welded onto the end of the upper frame rail.

The

fore rail was attached to a short stub of angle that was welded onto

the upper frame rail. Additionally, we had to cut the

handle used for the existing spare tire crane; it was replaced with a

scrap 1/2" drive socket to allow use if needed at some future point.

The

descending supports were measured, cut, welded and test installed.

Two

set screws were installed on the lateral and medial sides of the

receiver tube to prevent the assembly from movement.

The

mounting assembly was removed in preparation for painting.

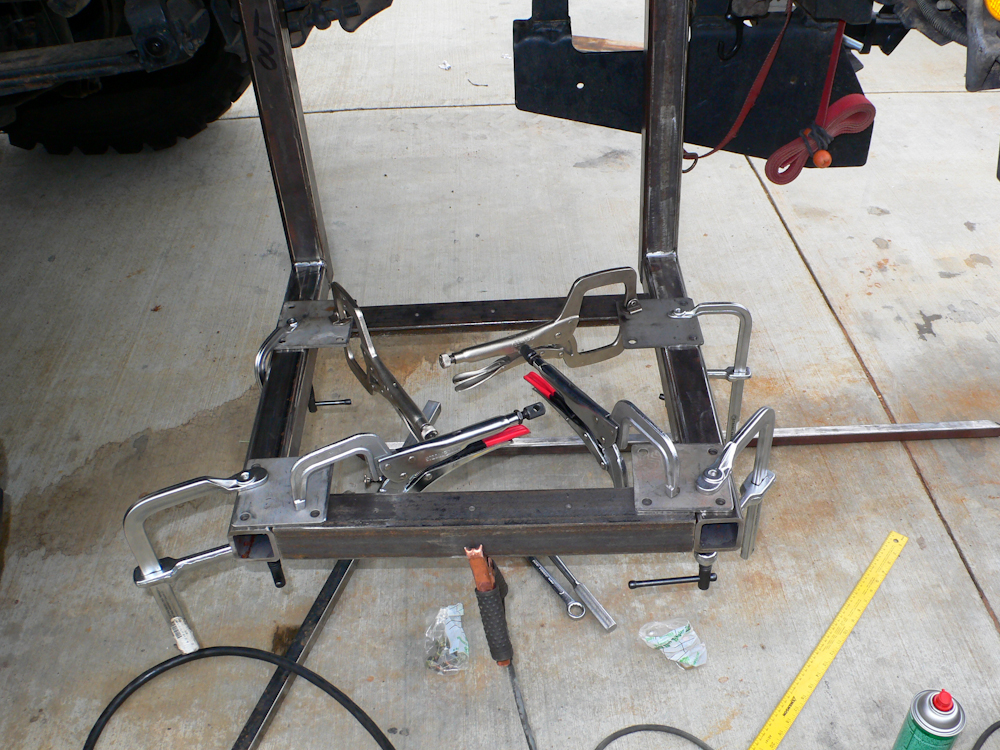

The

second mount was prepared for welding. The clamps were used to

insure that the assembly stayed in the proper geometry during

welding. Sadly, even thick walled material will warp when welded

so care must be exercised.

The

aft mounting bar was painted and installed.

The

fore bar was attached to the frame rails and the cargo box was attached

to the mount with a set of 1/4" pop rivets.

When

the cargo boxes were completed, we took the rig camping in the Borrego

Desert park near San Diego for a few days. The extra storage

space proved invaluable as we were able to transport a substantial

amount of fire wood and the fire ring assembly without impacting

anything else. Score one for the home team. Upon our

return, we attacked the front bash plate issue. During our trip

to Baja, we bent the step bar that allowed access to clean the front

windshield. Inspection of the damage revealed that the bottom of

the radiator was about 1/2" away from being torn out of the

mounts. It was a narrow miss, but it did highlight the need for a

robust protection assembly if we were going to continue doing hard-core

maneuvers while 'wheeling. So, a bash plate assembly was designed

based on the available space and low-impact attachment points on the

frame. The components of the assembly are shown above. On

the left are the descending "ears" that will hook to the tow eye.

The brace bar is 2x2x 0.25" steel tube. The aft mounting block

was machined out of more 2x2 tube. Thanks to Mark Mitchell for

the use of his mill.

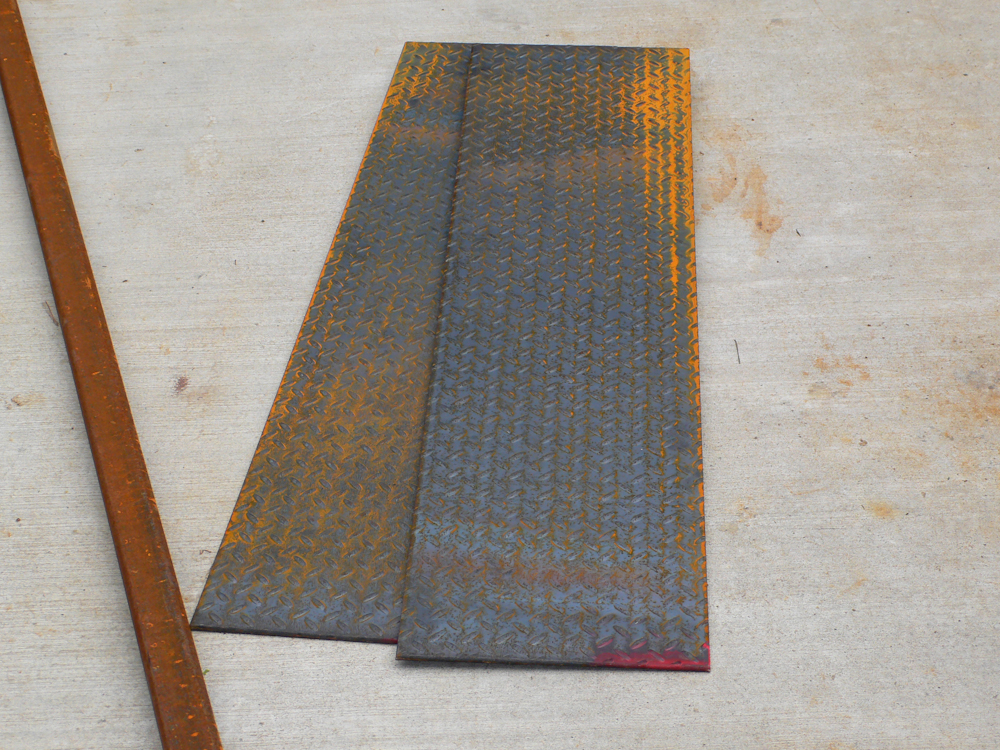

We

went to the steel store and found these 1/4" steel plates that were

nearly the right size.

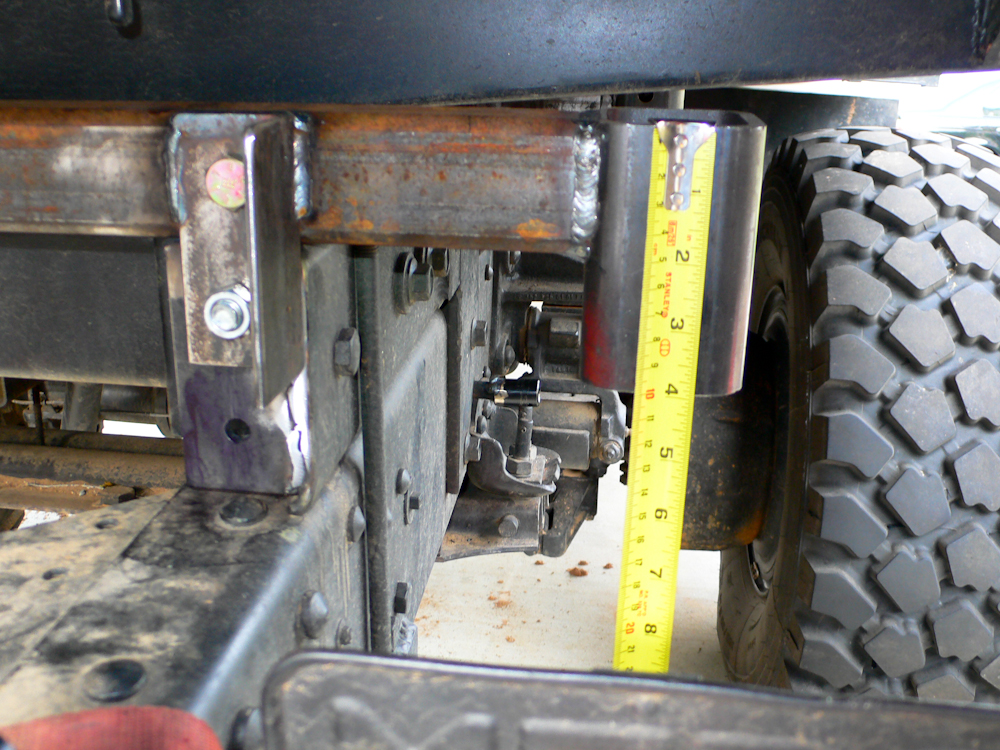

I

discovered through careful observation and measurement that the 2x2

tube would just fit in the saddle created by the existing mount for the

front sway bar. And, the geometry of the tube was close enough

that we could tap into the existing tow eyes on the front of the frame

without welding. In my heart, I felt that if we welded the bash

plate to the frame there would come a day when we would need to remove

it for some kind of mechanical service action. So, making the

whole assembly removable was a requirement. The proposed setup

did require some machine shop work and fabrication of some odd-geometry

cuts, but other than that, it should be straight-forward.

A

test fit of the brace bar as it will sit when connected to the frame.

The

descending ears on the front of the bar will attach to tow eyes on the

frame of the 1017. A 1" bolt was used for the connection.

Massive overkill, but it was what fit the hole in the eye.

Edges

to be welded needed to be chamfered to provide adequate weld

penetration given my wimpy welder. The welder will do a good job,

but only if the edges are prepared.

The

ears and end cap has been installed on the brace bar. Now we get

the cross member lined up for welding.

The

finished product ready to have the 1/4" diamond plate attached and then

be painted. We cut the 1/4 " plate with a new saw blade purchased

specifically for this task. The blade is called a "Diablo"

(available at Home Depot) and it fits in a standard circular saw.

The blade is carbide tipped and cut through the 1/4 plate like it was

butter. And, there were no burrs on the edge of the plate!

Kathleen and I were totally impressed.

Once

the bash place was painted and installed, we turned our attention to

the rear of the truck. Our expensive Yeti cooler is too big to

fit in even the biggest cargo box, so an alternative solution will be

needed. Our plan calls for construction of a frame that plugs into the

previously-installed hitch receivers that were welded to the top of the

frame rails. An additional receiver will be placed on top of the

conventional hitch receiver to provide additional support and allow the

use of the trailer hitch for towing without the requirement to remove

the frame.

The

deck on the platform will fold up when not in use. Above, the

hinge components are fabricated and checked. This design will

have some pretty tight tolerances to prevent rattles, so and part of

the construction we purchased a (better) used drill press to allow

drilling 5/8" holes through thick walled material.

The

descenders were carefully welded to prevent warping and then test

installed to determine the measurements of the balance of the

mount. Above, the secondary receiver mount was test positioned on

the trailer hitch frame to determine the fit before cutting.

The

descenders were held in place with conventional hitch pins. Note

that a 1/4" shim plate was needed under the auxiliary receiver to get

the geometry correct.

The

geometry and rotation of the hinges was tested by clamping some spare

angle to the hinge components.

The

lower receiver components were cut, drilled and welded. The deck

components were fabricated from stacked 1x1 tubing, visible at the

bottom of the photo.

The

deck frame was completed and then re-installed to the truck for

further hinge testing. The photo above shows the deck in the

retracted position.

The

photo above shows the hinge details. The welds in the photo above

look funky; the reason is that to prevent warping, we could only weld

about 1/2" at a time before letting the work piece cool down.

Kathleen assisted by using the air gun to accelerate the cooling.

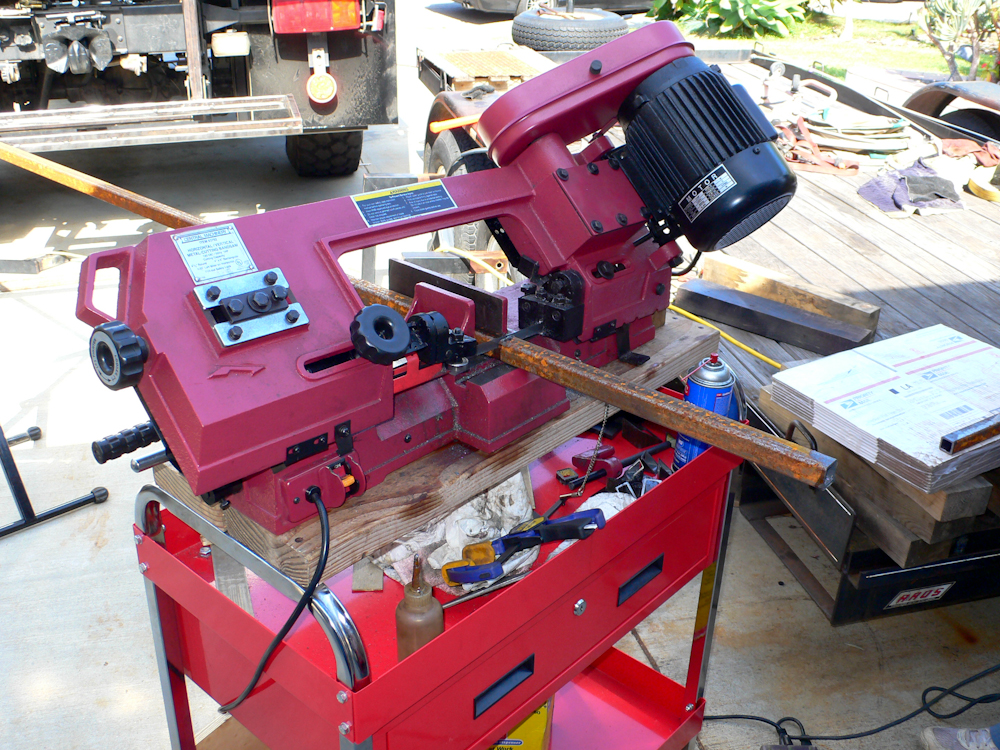

My

Harbor Freight band saw served us quite well during this project.

While not quite the quality I would have preferred, it cost about 1/5

of what I wanted and the work product was adequate to meet our

objectives. To be sure, there was a substantial amount of setup

to get the angles correct for the cuts, but that would have been the

case with any saw. After weeks of leaving the saw in the driveway

under a tarp (it is very heavy), I finally went back to Harbor and

purchased a cart to put it on so I can easily roll it into the garage

at the end of the day. Above, Kathleen cuts the internal deck

support members.

My

garage is not big enough to handle 20' lengths of steel tube, so we

left it sitting in the driveway for the duration of this project.

Rain rusted the hell out of the material making a thorough cleaning

necessary before final assembly and painting. Above, Kathleen

hits the tube with the angle grinder/wire wheel combo to remove the

rust.

The

additional support members were positioned and welded into the

deck. Again, in the photo above, the deck is shown in the

retracted position.

Finally,

the #9 expanded metal cover was added to the deck creating the load

bearing surface. The assembly is quite rigid and should easily be

capable of handling 500 pounds of cargo and still be retractable when

not needed. It should be noted that the height of the deck does

not impact the departure angle of the truck. The cargo boxes

determine that angle, followed closely by the bottom of the trailer

hitch assembly.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text

Copyright Bill Caid 2011, all rights reserved.

For your enjoyment only, not for commercial use.