This whole effort is starting to be very much like a job. Mounting the tires and wheels was not all that hard, but the bigger tires required cutting the fenders to prevent mechanical interferences. Our testing suggested that there would STILL be an interference with the steering drag link and spring stack if the wheel were turned to full lock. If the problem actually impacts our ability to manuever, the solution is to go with a slightly narrower tire and take these new tires and put them on the 1300. No harm, no foul.

The

photos below show the fender actions as well as installation of the cab

electrical system and the additon of the next set of cargo boxes.

Two more "big" boxes remain to be installed, but since we plan to head

to Baja California next week, we are delaying that installation until

we return.

The

photos below are what we saw.

A

made a guide attachment for my angle grinder and used a narrow metal

cutting blade. The saw did a great job of making a smooth

cut. We elected to not cut the rubber fender just yet for a

number of reasons.

Once

the fenders were cut, they were removed, sanded and painted. One

of the fenders had taken a hit during the truck's military duty and

needed a bit of pounding out. Due to time constraints, we decided

not to bondo the fender, just paint it and drive on. The fenders

are easy to remove and we will address the cosmetic issues when we get

the cab painted.

After

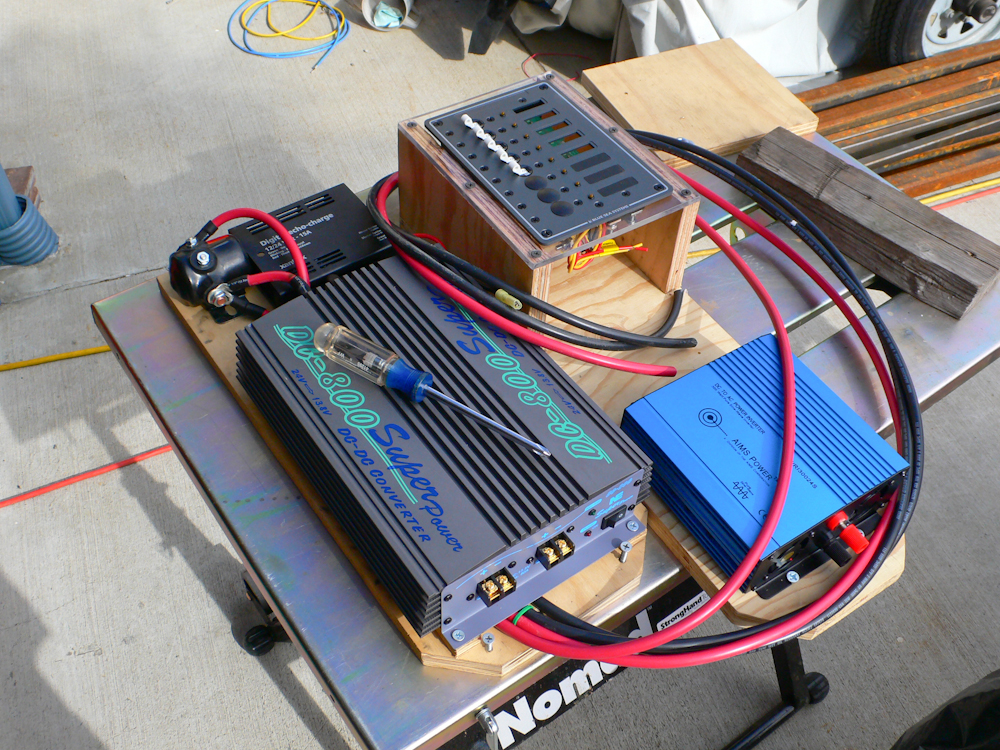

the fender, we returned to cab electrical actions. I had

previously fabricated mounting boards for the 2 sets of components that

needed to be installed in the cab. On the left is the 24V ->

12V converter, echo charger and control solenoid. On the right is

the 12V distribution panel and 24V -> 120 VAC inverter.

Getting

these large gauge wires in the correct locations and making the bend

radius meet the physical constraints was hard.

Kathleen

helped with setting up the wire runs and looming the final setup.

Doing

major electrical projects is time consuming and always produces a

mess. Above is the "normal" working environment: connectors,

meter, probe, crimper/stripper, knife, clippers, screws, wire and of

course the ever-present tie-wrap.

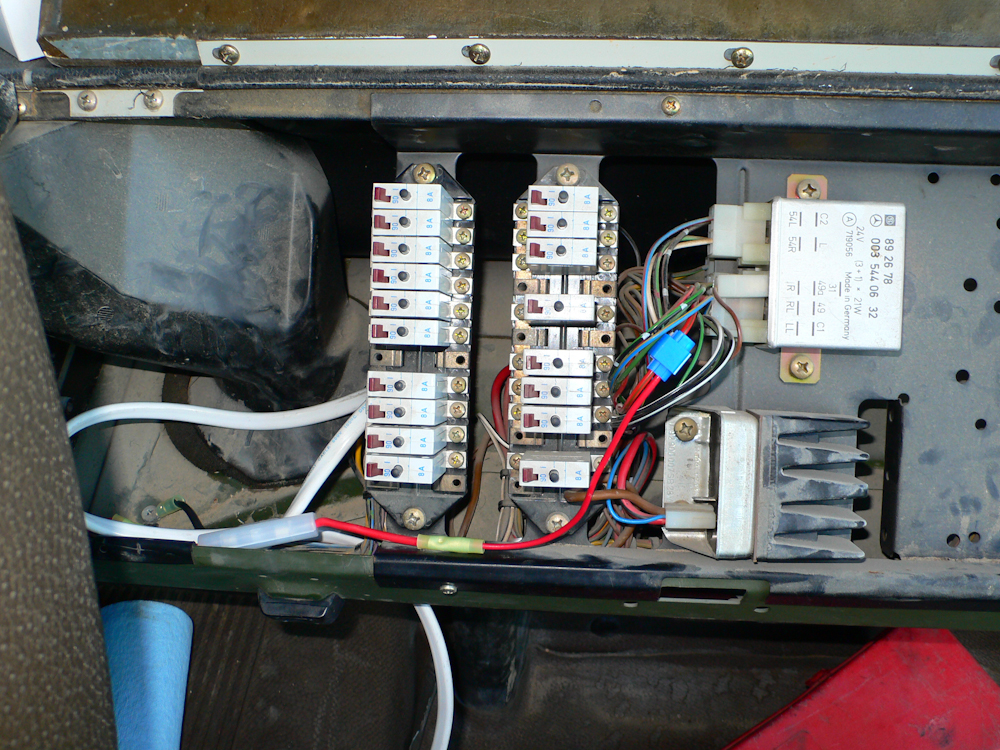

The

DC distribution panel went in pretty easy, but I had already fabricated

the parts. All we had to do was connect the wires in the correct

places. There was, however, a minor annoyance. This setup

required some non-standard circuit breakers which required several

trips to West Marine to obtain. I did win in the end however.

The

24V -> 12V converter was hooked up with a 24V continuous duty

solenoid to insure that power to the unit was shut off when the

ignition key is removed. The echo charger is used to charge the

"house" batteries while the 1017 engine is running.

Getting

the control signal for the solenoid required diving into the main

circuit breaker panel for the 1017. Sadly, I do not have a

circuit diagram, so I had to use my probe to choose an appropriate wire

to tap in to. The connection was made with 12 gauge marine safety

cable (white wire).

The

high current 24V source was run directly from the battery terminals

using #6 cables. These cables had to attach to power posts on the

fender to allow easy disconnection should the cab need to be raised for

maintenance actions. The echo charger 12V line is a separate

cable through a separate connection. The Y branch of the loom

contains the coax cable for the 2 meter radio antenna on the roof of

the cab.

I

got the power posts from, no surprise, West Marine. The posts

came with the nifty plastic insulating caps. Running the pair of

#6 cables in looms was somewhat of a challenge, but we did find a nice

routing.

When

the 12V was in and the antenna cable was run, I mounted a new Icom 2200

2m transciever.

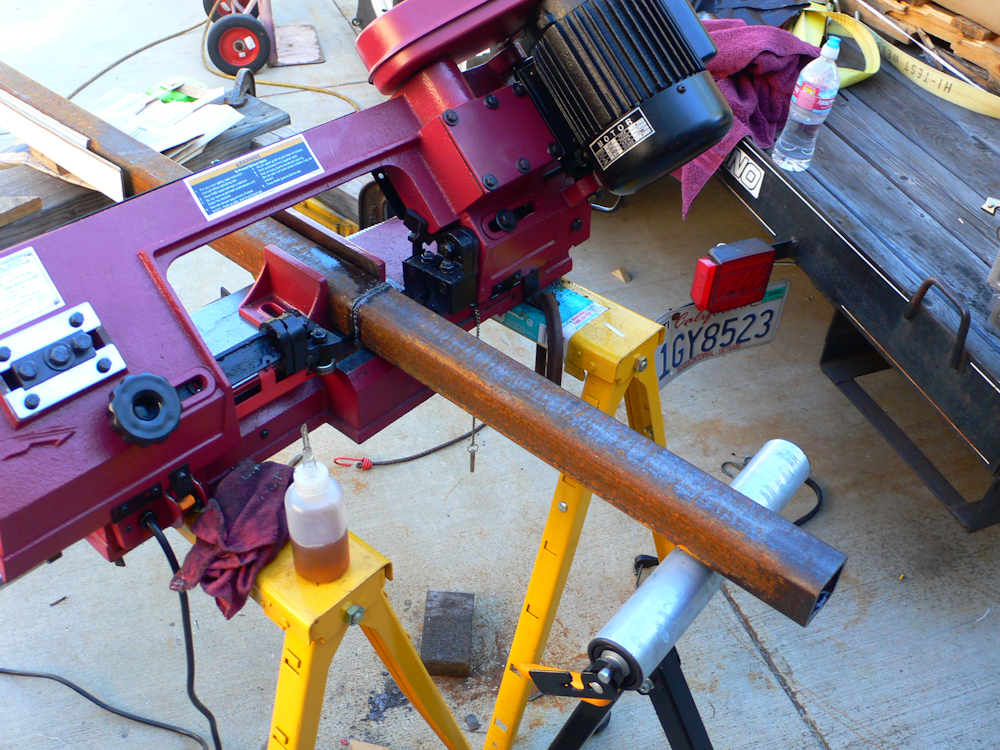

Once

the electrical was stable, we went back to steel work for the cargo

boxes. The mounts for the 24x24x36" boxes were cut from 2"x1/4"

square tubing. My el-cheapo band saw from Harbor Freight still

works fine.

Kathleen

cleans off the surface rust from the tubing while I cut the balance of

the parts. My 3D corner jig is visible at the lower left of the

photo above. It worked great.

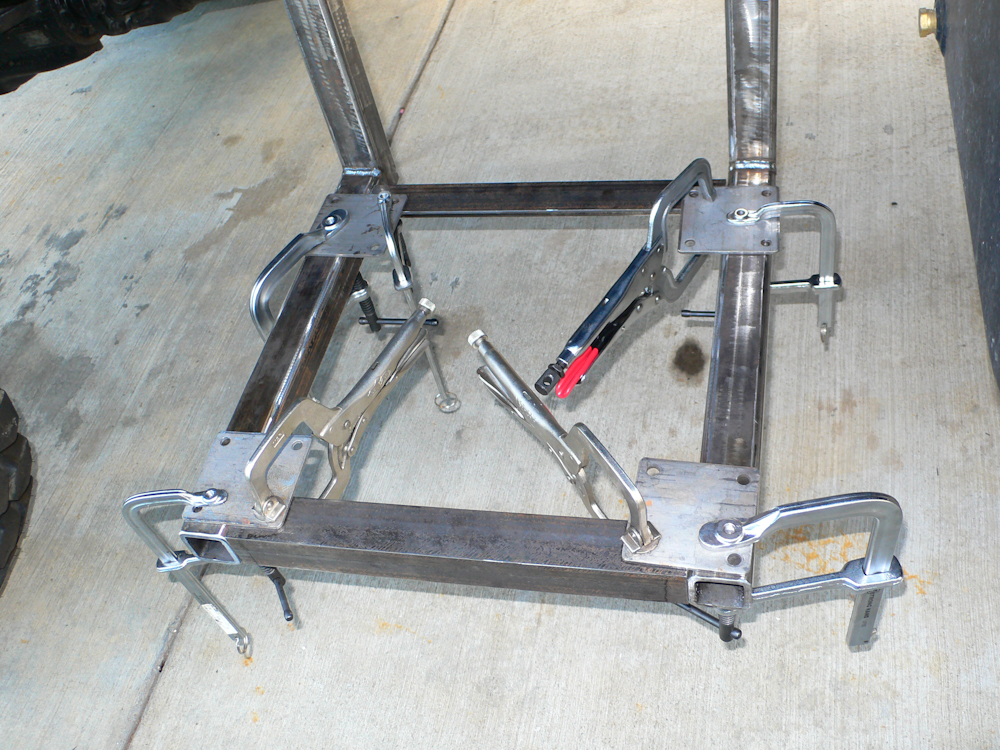

The

brackets were test fitted in the mounts.

Floor

braces were cut, fitted and welded into place.

Mounts

for the camper cargo boxes were fabricated, welded and primed.

Due

to the geometry of the frame, the mounts were assymetrical and each one

was unique slowing the installation.

Kathleen

whined enough about the decaying seats in the 1017 to get me to take

action. The seats are just old and the vinyl is cracked and the

foam is eroded. A trip to the upholstery shop is planned, but due

to scheduling, we could not get a slot before our baja trip. So,

to silence the noise, I agreed to attempt to get new seats before the

trip. We made a trip to one of the many junk yards in Chula Vista

next to the Mexican border and found these seats. We had to

remove them ourselves and carry them up a big hill to get out of the

place, but the price was right: $20 for BOTH seats. The bad news

was that when we got the seats to where we could carefully inspect both

the 1017 stock seats and these, we both agreed that this would be a

lengthy and complex steel work project and nothing that could be

reasonably completed before our departure. So, the seats went

into the garage and the action went "onto the stack" for prosecution

upon our return.

We

prepped, primed and painted the box mounting frames and installed the

boxes. All the boxes were pop riveted to their lower supports to

prevent shifting when off road. The manufacturer's stickers were

removed after this photo.

We

set up for a road test after the boxes were mounted. These

tires/wheels are virgin and have not been out of the driveway since

they were mounted a few weeks ago. My 1300 is visible at the far

right of the photo above.

A

view of the passenger side shows the new cargo boxes that have been

mounted since the last report. Note that 2 more big boxes are

planned to be mounted aft of the rear wheels at the same height, and

with the same mounting method, as the current big box.

Kathleen

performs her walk-around before the test drive. Note that we now

have valid California plates for the truck. Our "disagreement"

with the DMV was resolved in my favor.

As with every other segment I have posted, this was more work, more time consuming and more expensive than expected. But, also like the other segments, we prevailed and have been happy with the results.

Up next: a

shakedown trip to Baja with the San Diego unimog contingent.

Then, the balance of the cargo boxes, completed cab electrical, carpet,

reupholstry, cab paint, cabinet work in the camper and damage repair

from the baja trip (assuming there is damage).

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2011, all rights

reserved.

For your enjoyment only, not for commercial use.