We continued our enhancements to

the 1017A. Generally speaking, we were limited by the ability of

our parts vendors to deliver our needed components to us in a timely

fashion. Once we had all the necessary stuff, things went pretty

smoothly. This section of enhancements was focused on installing

body-mounted tool boxes and the super-single tires/wheels. We

ordered 8 tool boxes with the intention of installing 5 on the camper

body and 3 "big" boxes on mounts attached to the frame itself.

Mounting the camper boxes was a challenge due to the odd geometry of

the camper. We did not install the bigger boxes during this

segment due to the arrival of the wheels and tires. The wheels

were ordered through our parts supplier and were delivered through

Mercedes in Germany. The whole cycle took almost 4 months end to

end. The tires were purchased online and arrived after only a

week or so.

The photos below are what we saw.

For the cab, we ordered

3-24"x14"x16" boxes and 2-30" boxes. One 24" box was used for the

utility connections and the 30" box will be used for general

storage. Brackets were fabricated and welded to the camper

frame. The boxes were mounted flush with the underside of the

floor of the camper between the frame rails.

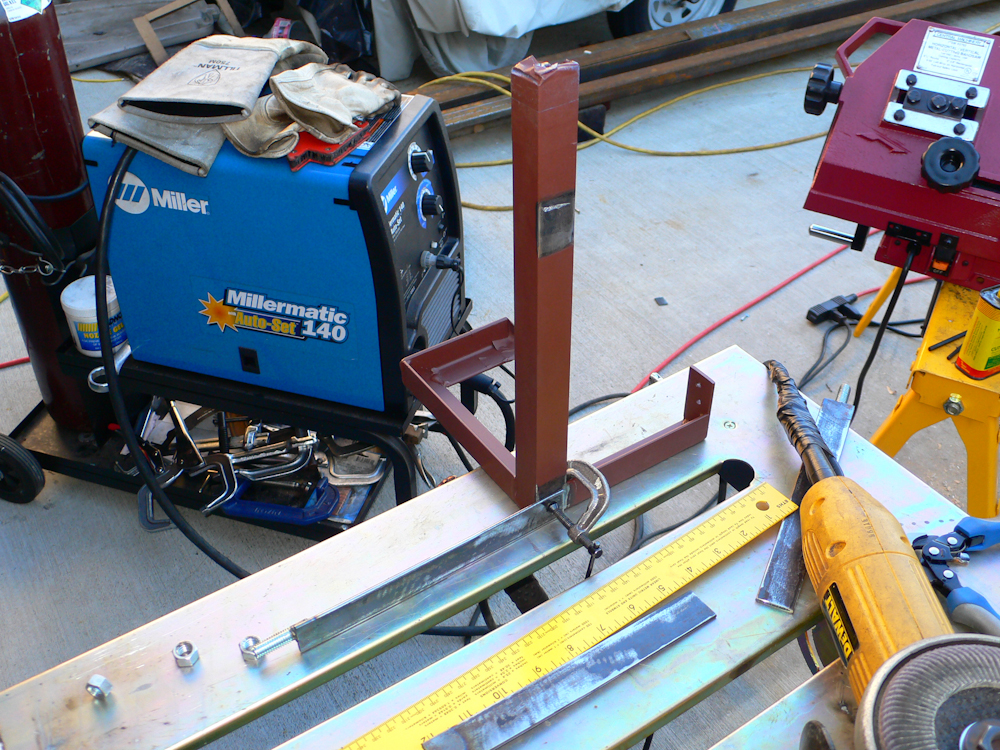

The rear mounting frame was much

more complex and had to be fitted, fabricated and primed before welding

to the frame. Above, the final fabrication actions are performed

prior to welding the frame into place.

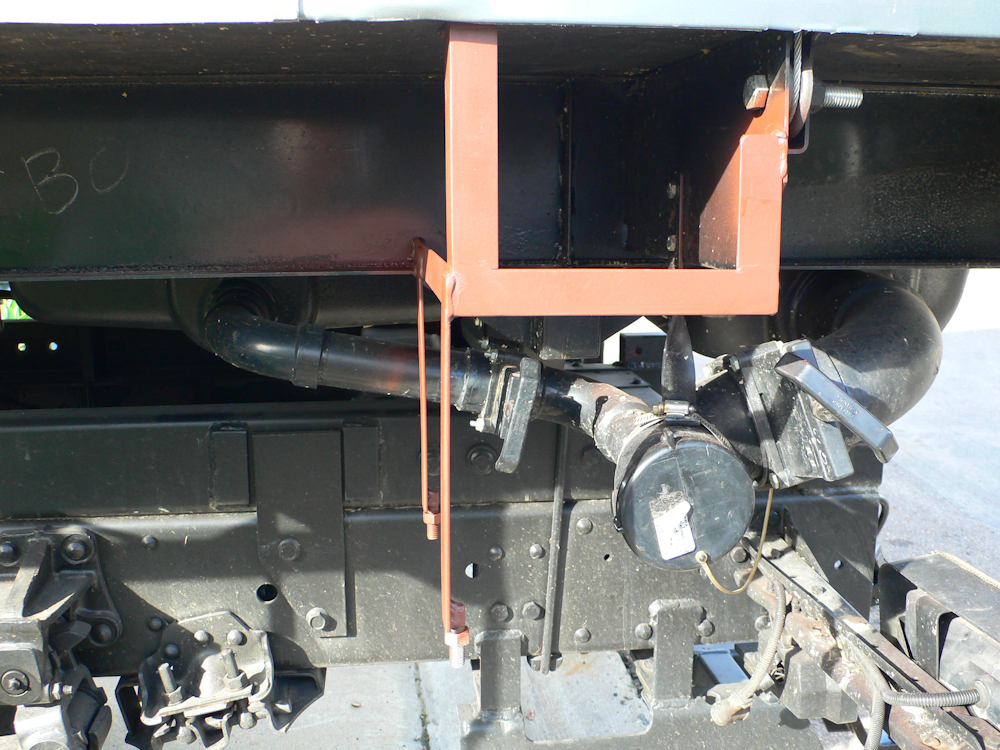

The frame was welded into place

and the welds were then primed prior to painting.

Whoa!! WTF is this??

This gnarly insect is about 1.5" inches long and I discovered it

between my knees as I was working under the truck.

After the 3 tool boxes were

installed, we moved on to tires. I traded Roberto Espinoza for 4

Michelin 395/85R20 XZL tires that he had. His office was flooded

during the recent rains, so I was storing them for him. After the

balance of my tire/wheel parts arrived, I traded him the 4 I had for 4

more that were ordered online. These tires are brutes; big and

heavy. Notice the diameter of the tire relative to my car carrier

trailer.

The first thing that had to happen

was a "test fit" to insure that the over-sized tires would fit as

needed. To do that required removal of the existing 22.5"

heavy-duty truck tires. These lug nuts were TIGHT and required

several cascaded cheater bars to provide sufficient torque to crack

them loose. The bar that came with the truck did not fare well,

so we resorted to using an X wrench that came with my 1300.

The bar that came with the 1017A

was not up to the task; it was just not robust enough to handle the

torque. It bent like a pretzel under stress. The photo

above shows the bar AFTER it was straightened. I have

subsequently purchased several hardened bars to use with the cheater.

The test fitting went OK, there

were no "unknown" interferences. In the photo above, the tire is

not fully mounted. There is no locking ring on the tire and no

valve stem in the rim. See below for details.

The special valve stems needed for

installing the tires were ordered but not here, so we moved on to

electrical actions. High-current cables were strung from

the 24V battery array to the cab of the 1017. Mounting posts for

the electrical connections were attached to the fender and preparations

were made for the final run of cable into the cab. The mounting

boards for the electrical components were cut and the components were

mounted. Above are 2 boards that will be attached into the "cargo

bubble" on the back of the cab. The bubble has a vertical

stiffener and on the driver's side the left board will be

attached. The other board will be on the passenger's side.

The left board has the 24V->12V converter, echo charger and 24V

enable solenoid. The right board is the 12VDC circuit breaker

panel and 24V->120VAC inverter for cab appliances like laptop and

cell phone chargers. I did not complete the electrical

installation as the remaining tire components finally arrived and we

switched back to that task.

The front of the truck was jacked

up and the OEM wheel was removed. The 1017A has drum brakes

all-around and these are big drums.

Why is that shovel in all these

photos? The answer is that it is the trick to changing large

tires. A standard #2 spade-point shovel provides an excellent

lifting method for large tires. It takes a hard task and makes it

easy. In fact, you can change a tire with only one person if you

have a shovel and the truck is not jacked too high. In addition

to lifting, in also acts as a "sled" to slide the tire away from the

wheel when removing the tire from the hub. Frankly, I doubt that

it would be possible to do this action without this sort of tool.

The new super-single wheels are

made of 12mm thick rolled plate. These wheels are very, very

heavy. These are 4 part wheels: the cup, the sealing

gasket, the outer flange, and the locking ring.

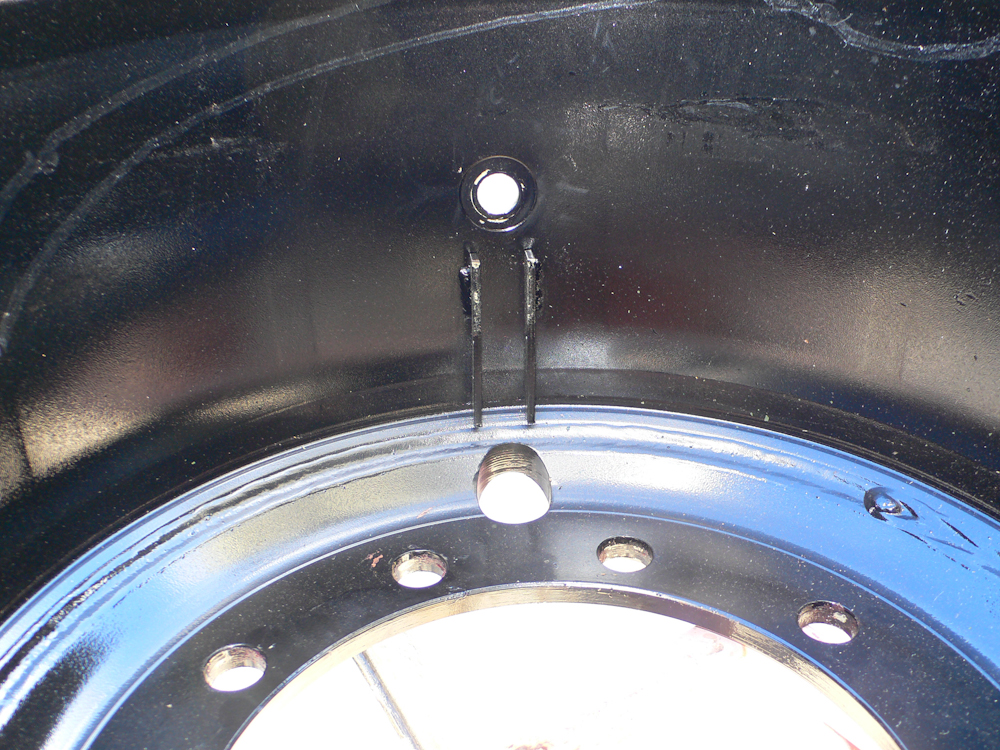

The inside of the wheel has

protection plates for the valve stems. The corner of these plates

would be ground down to provide clearance with the brake drums.

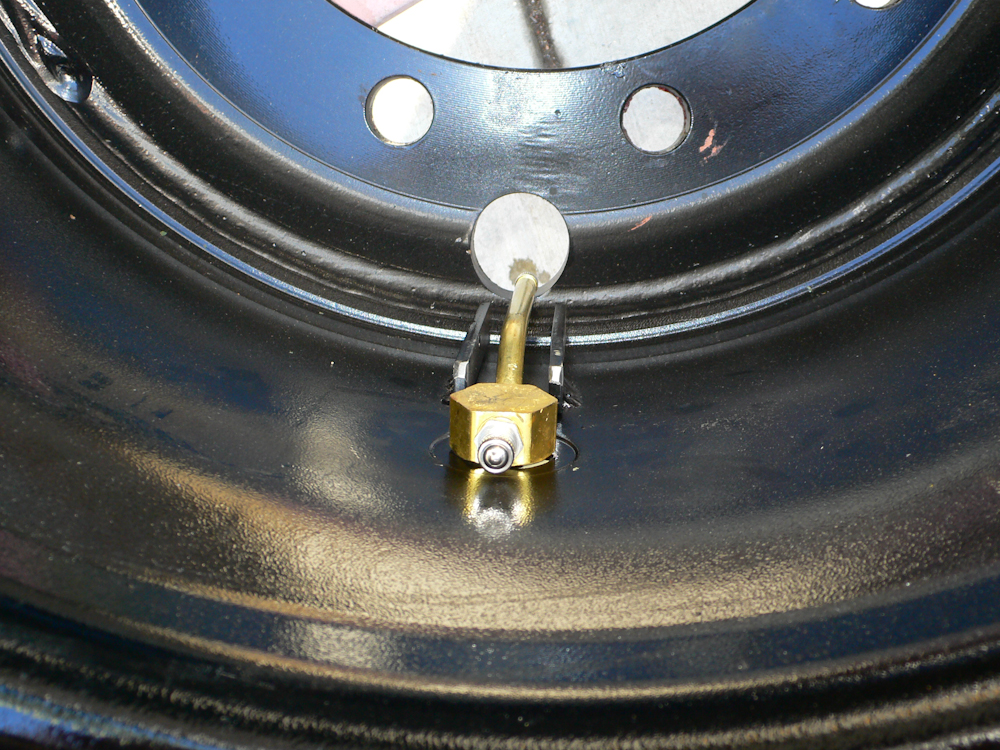

These valve stems were destined

for a US military 6x6, but also fit these rims. These were about

$35 each, but a far cry from the $100 each that Mercedes wanted for

something that could only be filled from one side of the wheel.

The bar on the left of the photo above is my new Ken-Tool hardened bead

breaker/cheater bar for cracking lug nuts. I got it online from

Gempler's. They have tons of industrial tire tools and fast

delivery.

The mounted tire valve stem before

the corners were ground off.

To make the stems fit, a trough in

the drum was cut with a pneumatic die grinder and carbide bit. I

used layout dye to test for mechanical interferences with the

stem. A number of grinding passes were required before the trough

was deep enough.

The front tire was installed after

the hub fit in the trough. These big tires totally fill the wheel

well. In fact, portions of the fender will have to be cut to

eliminate possible intereferences when the truck is off-camber.

Note the electrical cable coming out of the underside of the cab cargo

bubble. This is the 12 echo charger cable to change the house

batteries when the truck is running. The cab is 24V, so a voltage

conversion is required as well as a charge controller circuit (echo

charger) to accomplish the mission.

In the rear, the truck was

equipped with dual wheels when shipped from the factory. 2 rear

wheels were replaced with one super-single. Note that the "cup"

is in on the rear, out on the front. In the cavity above the

wheel is the house lift hydraulic pump.

The first tire that we installed

developed a leak due to operator error, so we pulled it off the rim and

addressed the situation. Afterwards, we pulled the truck into the

street as a test. Note that the truck is now quite high relative

to Kathleen's 5'8" height.

None of the tool boxes on the

passenger's side have been mounted yet. But at the rear, under the

camper, you can see the mounting frames for the leveling blocks and the

storage area for the stairs.

The 3 tool boxes on the driver's side are clearly visible above.

Next up: body work to cut a portion of the front

fenders to remove the possibility of mechanical interferences with the

tire. We will also remove the leading mud flaps on the front of

the tire. The cab electrical must be completed as well as the

mounting the remaining 5 tool boxes.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text

Copyright Bill Caid 2011, all rights reserved.

For your enjoyment only, not for commercial use.