We had been waiting for a bunch

of parts to come from our vendors. As it is with most things,

they did not arrive in synchrony. So, we had to wait until we had

the required parts before moving on to the next set of actions.

The original plan was to have the high-current DC switches and fuses

contained in an external tool box. This box would also provide a

home for the 30 amp electrical cord and other utilities. The tool

boxes were ordered in October, but I needed various sizes that were not

commonly available. After much web work, I found that San Diego

Trailer Supply would order the required boxes. The only bad news

was that the boxes would not arrive until "January". On December

30th, they called and stated that the boxes had arrived and that I had

to come pick them up. A whole pallet of boxes, about $3K worth as

it turns out. Since the mog had leaking brake seals due to a

driver error causing an over-heating situation (all I will say is that

I was not driving), we secured the 1017, attached my flatbed trailer

and headed to get the tool boxes.

The photos below are what we saw.

We had a small "accident" with our

tire crane. During testing, I discovered what I consider to be a

design flaw in the control switch. Basically, the switch is two

push buttons. No problem there, but the issue is that the

direction control solenoid valve on the hydraulic motor can change

directions nearly instantly. Meanwhile, the pump motor is ramping

down causing the boom to whip back and forth. With a 400 pound

tire/wheel combo at the end of the cable, that would produce

interesting results. The problem only occurs when you are

retracting the cylinder. I attempted to rework the switch, but

during testing, a small bit of stripped insulation from one of the

wires I was working on got caught inside the switch mechanism. On

the next test run, the motor stuck in the "on" position, driving the

cylinder into the stop. But, since there was another few inches

of travel left on the cylinder, it did a great job of bending the

frame. Make no mistake about it, hydraulics are strong. The

solution to the problem, aside from unseating the lodged debris from

the switch, was to fabricate a switch assembly that would prevent the

issue from happening again. And, since I was at it, I folded in a

switch for the winch motor as well and placed it on the same control

dongle. I also added several safety circuits to prevent things

from getting "sideways" again. After the construction and

installation was complete, we needed a full-weight test. The new

control dongle is the gray box at the extreme left of the photo, at the

bottom and is only partially visible. Kathleen assisted in the

test but was none-too-happy about being close to a full-size XM47 on

the end of the winch cable. Note the expression on her face.

All components of the system

performed as designed and we were both pleased. Kathleen was

especially pleased when that big tire was close to the ground and not

over her head. The crane picked up the wheel/tire combo without

missing a beat.

We had to install flooring for the

tire crane area, but before we could do that, we had to paint one of

the can racks. Above, Kathleen suits up for a bit of wire wheel

work in preparation for painting.

The can rack is a standard-issue

unimog rack that I got from Rob Pickering. The frame needed a bit

of reinforcement, but was generally in good shape if you like

olive-drab. The color scheme for the 1017 is black and white, so

a repaint was in order. Above, Kathleen got all the old rust off

in preparation for priming and painting.

Sometimes, I do things that I do not understand. I am not sure why I did not take a "real" photo of the crane control dongle, but this is the best I have. The solution to the whipsaw effect was to separate the direction control from the motor control. All that was required was to select the direction of the valve and hold it constant while the pump was in motion. That was a costly discovery.

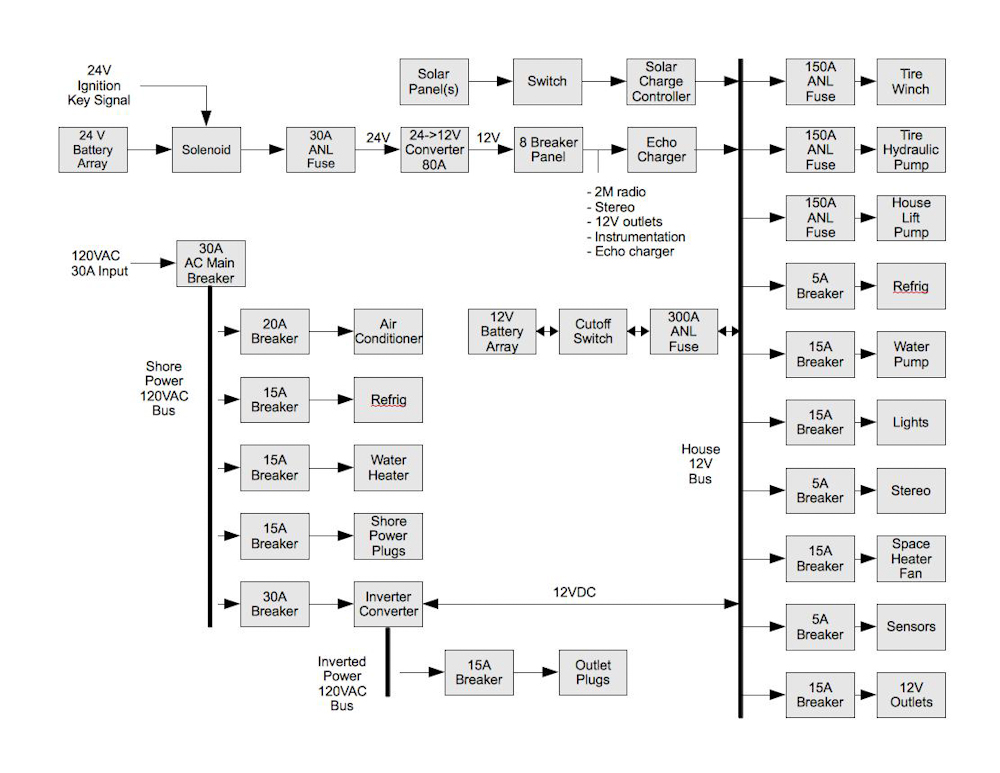

The electrical system for the 1017

is somewhat complex. There are lots of "things" and of course,

the truck itself is 24V and the camper is 12V. And, most

electronic components available here in the US are 12V, so a 24->12V

converter will be required in the cab. But, I include the

diagram here for reference to get a feel for the scope of the effort.

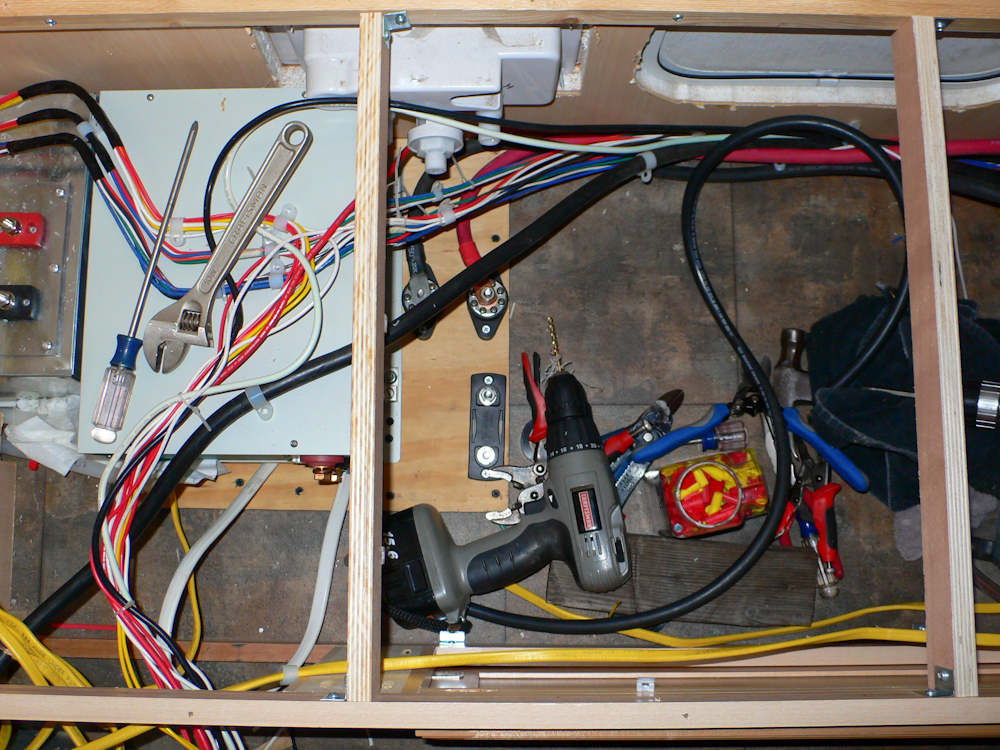

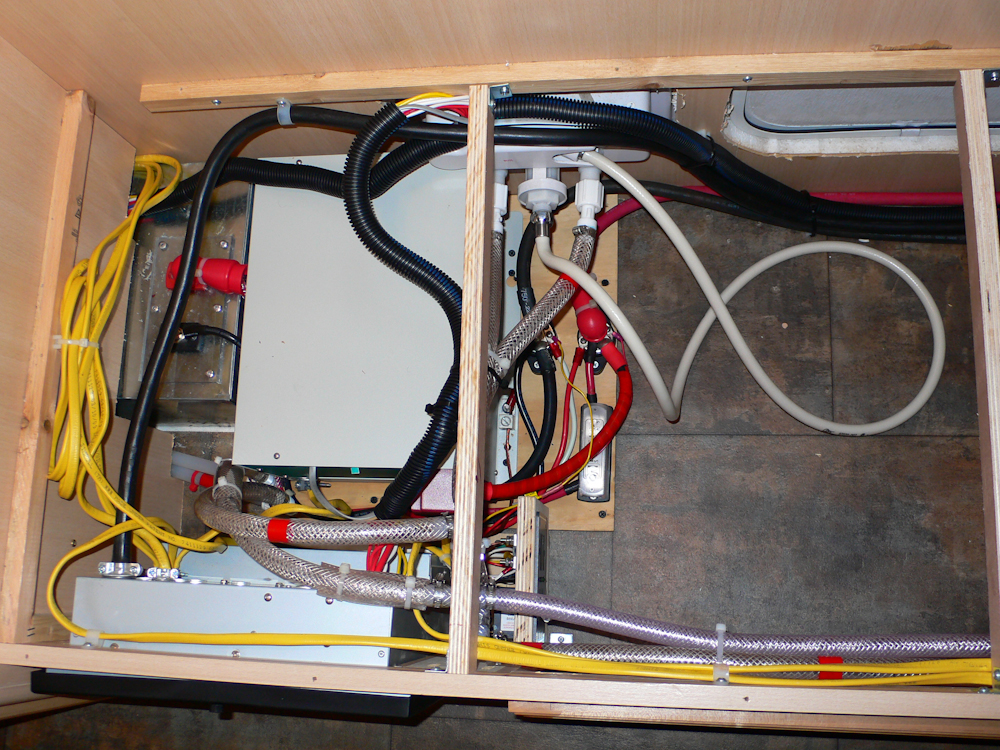

My inverter had finally

arrived. I ordered one from a discount marine store on the web

and it arrived damaged. 3 weeks were expended "discussing" the

issue, but it was finally resolved. My response was to order from

a different vendor that was more reputable. That unit, a Xantrex

2KW device, arrived with no damage. The planned installation area

was under the couch area. But, upon inspection and much to my

dismay, the area was crowded with plumbing. To install the

(heavy) inverter in the correct location would require removal of the

existing plumbing and a re-routing of the pipes. Simple things

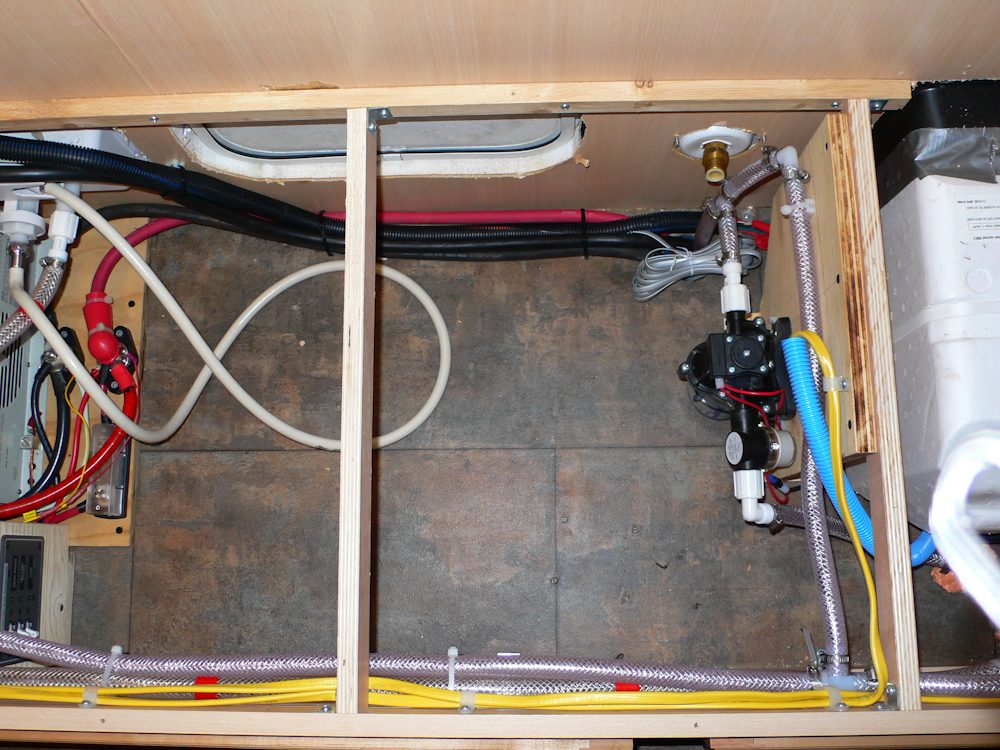

are never simple. In the photo above, you can see the PEX pipe

that was used in the Hi-Lo camper. The inverter is the gray box

at the right of the photo with the tools on it. The plywood panel

will serve as the base for the inverter and the mount for the high

current power posts. The sheet metal box at the left is the wheel

well for the trailer.

The guys that assembled this

camper did not even put the water pump in straight. The angle

above is the way it was. That, of course, will change in short

order. One of the other side effects of their "design" was that

the space under the couch was unusable for storage. So, there

were multiple reasons for re-plumbing the cabin. Plus, as I

planned the effort, I discovered that pex fittings are not commonly

available. The ones that are available are very expensive, $6+

per fitting and I could not find a local vendor for the pipe

either. So, the pex has gotta go.

I got my tubing cutters out and

nuked all the pex pipe. The pipe will be replaced with standard

reinforced plastic tubing, commonly available at hardware stores.

There were a ton of wires back there and none were labeled. Great

care was required.

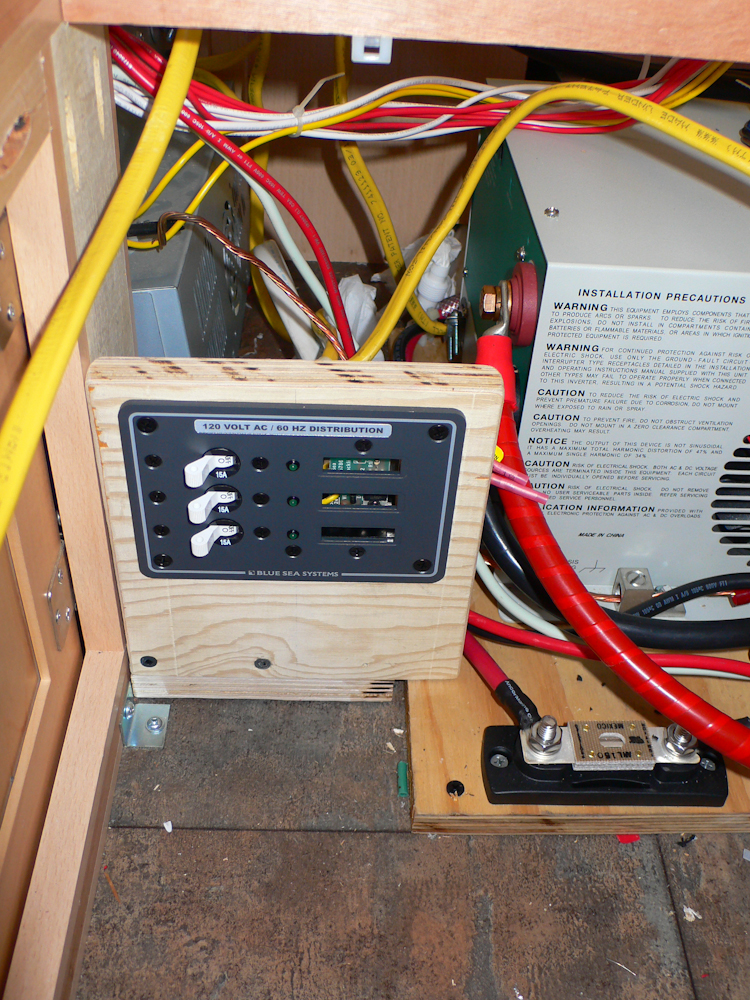

Happily, I was able to re-use the

AC wiring and for whatever reason, the AC circuits were much better

designed than the plumbing. Installation of the inverter was

straightforward but required creation of an AC sub-panel to provide

circuit breakers for the inverter circuits. An expensive trip to

West Marine got me what I needed. Note the 150 amp DC fuse in the

photo above. That fuse is for the house hydraulic lift pump

motor. Their original design had no fuse or circuit breaker on

that high current line!

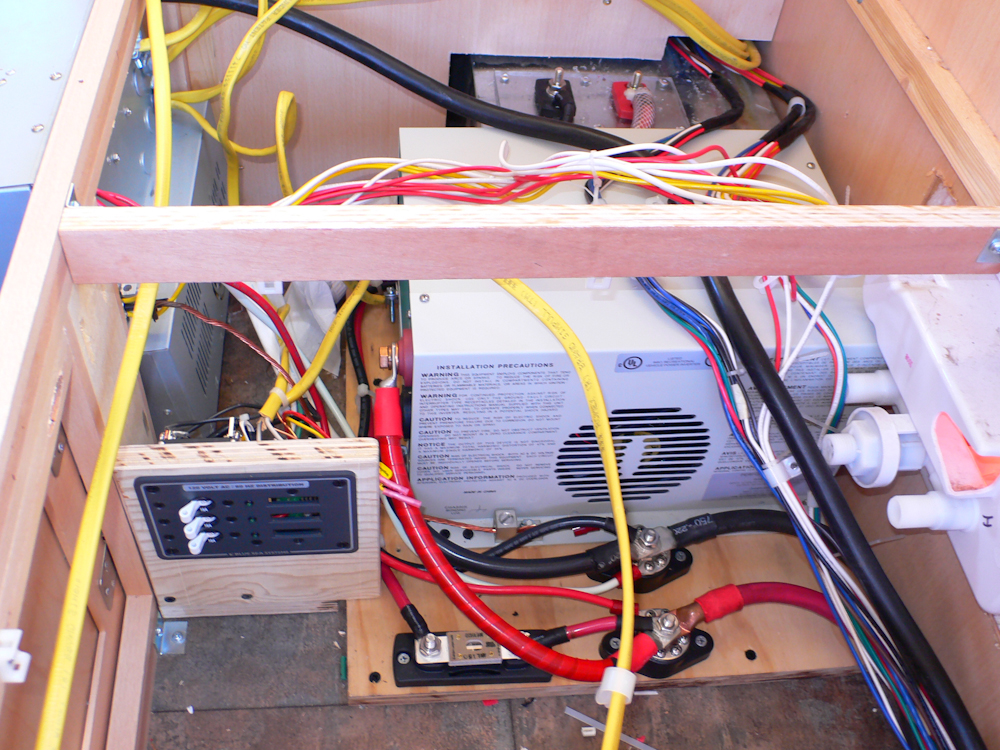

The house lift pump lines were run

from the power posts around the front of the inverter to a pair of

feed-throughs visible at the top of the photo. The pump is

mounted in the wheel well on the other side of the feed throughs.

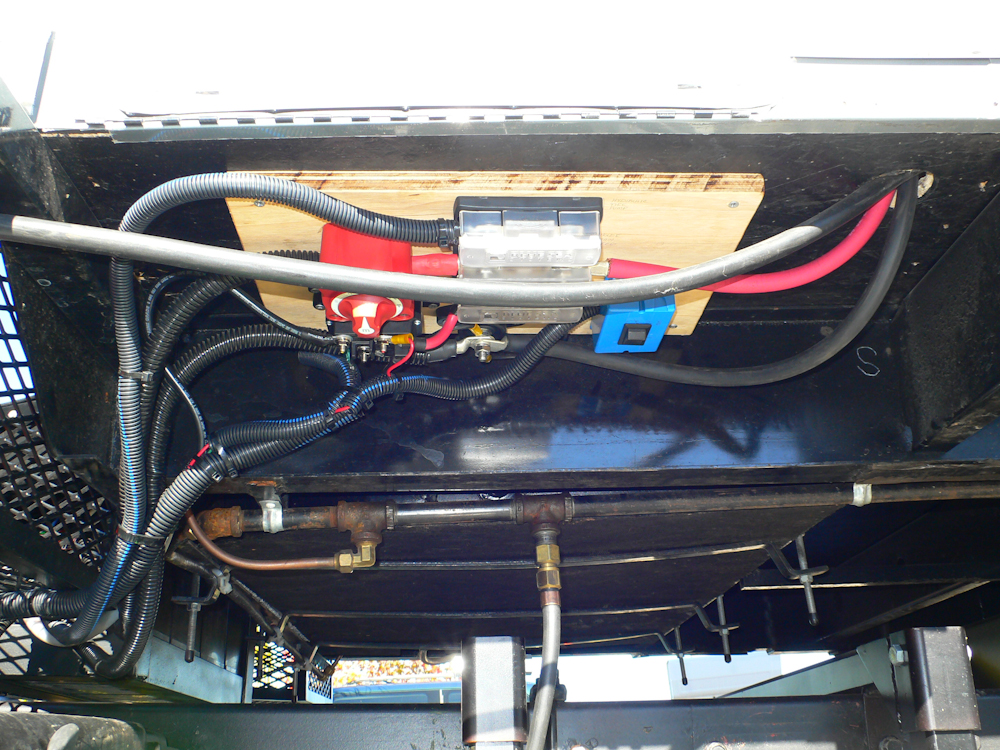

In the middle of our efforts, the

tool boxes arrived. Since the mog had brake issues, and I have no

other truck except the 1017, we had to suspend our efforts in the

camper to get the boxes. Once things were secured, we lowered the

top. That action required electrical completion of the DC

circuits. Once the top was lowered, I took a few photos of the

inside to show clearance of the components.

There is still some room left

above the refrigerator, so I may build a shelf or cabinet there.

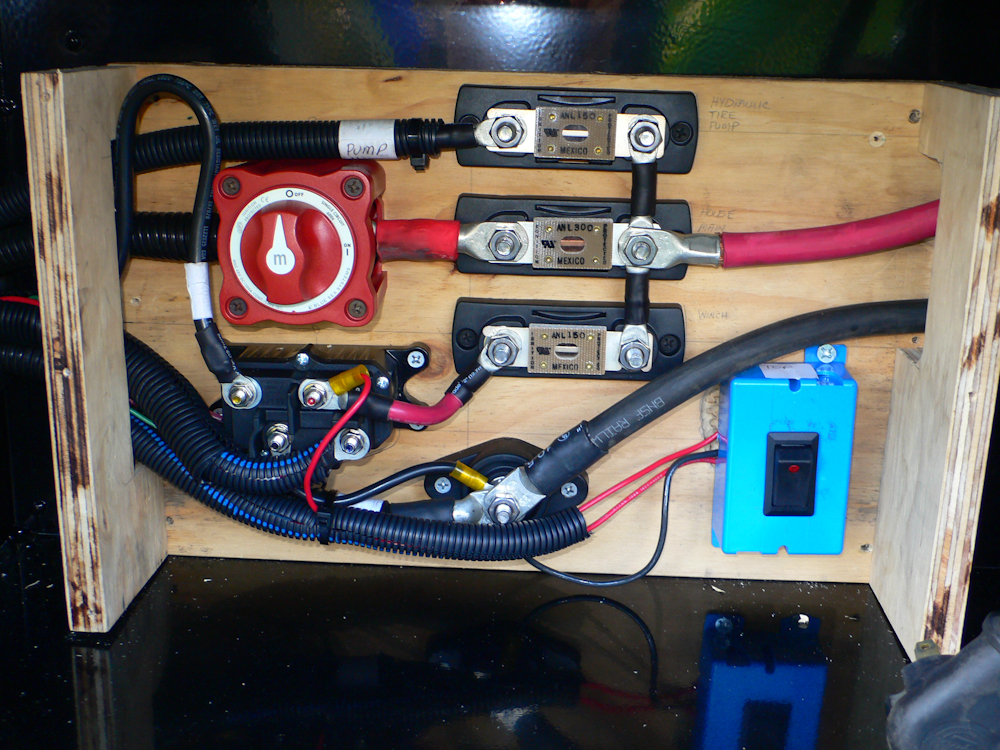

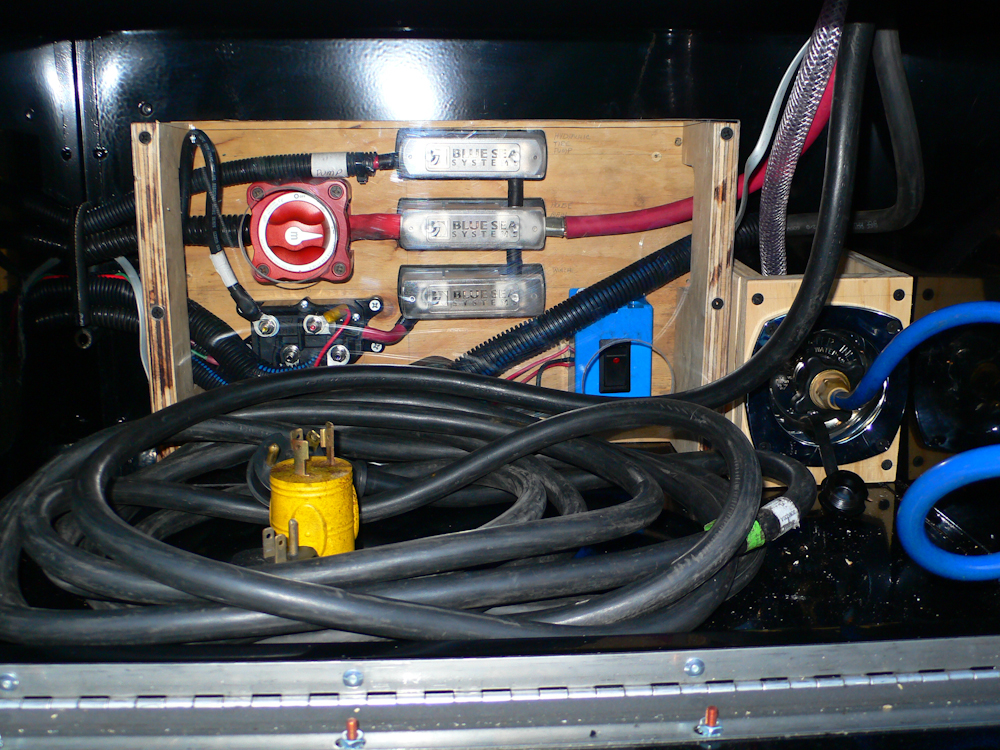

Once we had our tool boxes, we had

to "undo" some of our electrical controls. The board above was

designed to fit inside one of the tool boxes to provide both physical

and weather protection. This board had to be disassembled to move

to the next step. Interestingly, initial construction was

required to test the tire crane, so no effort was wasted.

There were a whole pallet of tool

boxes. In the shot above, I had already removed one layer of the

pallet to inspect the boxes.

The boxes looked good: robust and

the sizes that I ordered (always a nice gesture), so we moved ahead

with fabrication of the mounts.

The boxes were intended to fit

between the cross members on the camper, outboard of the main

frame. Attachment straps were fabricated with threaded ends

added. The photo above shows a test fit. We rejected this

design and came up with an alternative that had less offset between the

box and the descenders.

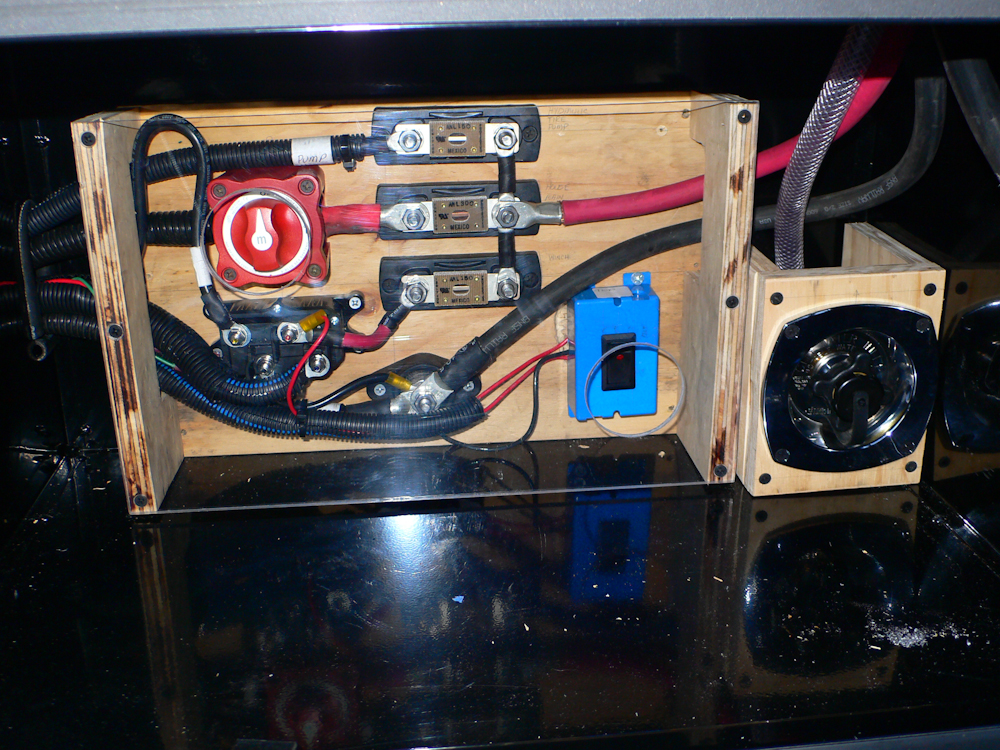

Once the box was satisfactorily

installed, we could then proceed with the balance of the electrical

installation. Stand offs were added to the mounting board to

provide an attachment point for mechanical protection of the

components. The blue switch is the "crane enable" switch to

prevent a damaged dongle from engaging the winch or pump

unintentionally. Ooh,that would be bad.

Ingress and egress holes were cut

into the tool box to allow routing of the cables into the box. A

Plexiglas cover was cut, drilled and installed. Note the access

holes for the 2 switches. In addition, the external water

connection was added to replace the stock connection.

Once the tool box was in place, we

could finish the wiring above. All the wiring was sanitized and

placed in looms. The new plumping is visible at the bottom of the

photo. All things being equal, I would have preferred to not mix

plumbing and electrical for obvious reasons. But, to meet that

criteria would have required a massive re-do of the whole system.

So, we did it with care and checked our work multiple times. But,

one thing for sure, if a hose were to burst or a connection were to

come loose, it would be very interesting.

The right side of the compartment

is visible in the photo above. Note that the water pump has been

mounted vertically to provide more room. Also note that the old

water ingress point has been decommissioned; the old fitting did not

have a pressure reducer and therefore you had to add one outside each

time before use. My ingress fitting has a built-in reducer

preventing potential mistakes. I just have to remember to NOT use the

old fitting.

The final tool box configuration

with the coiled 30 amp cable stowed in place. Also, the shore

water hose was installed and tightened. This whole segment was a

ton of work.

The final act was to install the

remote control/monitor for the inverter. There was just enough

room behind the face of the cabinet to install it without generating an

interference with the drawer.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text

Copyright Bill Caid 2011, all rights reserved.

For your enjoyment only, not for commercial use.