This

portion of the build-out was fraught with frustration. There were

a large number of components that had to be assembled to make the

system as a whole functional. Most of these components were

acquired online through vendors that I had never used before.

Additionally, we purchased a substantial quantity of stuff from

familiar vendors, such as West Marine, to get the task completed.

Sadly, this portion of the effort spanned many weeks and offered us a

number of challenges.

The photos below are what we saw.

We

actually used the 1017A as a camper over Thanksgiving. We went to

the desert with our Unimog buddies and took our quads on our

trailer. We had a great time and the truck performed as

expected. But, it would have been nice to have had 120 VAC in the

cabin. We had not yet installed the inverter, so we had to rely

on our on-board Honda generator for AC service while camped. The

generator worked as expected, so we were happy. Upon our return

to San Diego, we started in on the high-current electrical

modifications required to make the tire crane system operate.

Above is a photo of the first stages of the high current control

board. Everything that was done had to be done as a temporary

solution as my tool boxes were still on order and were not expected for

at least another 2 months. So, I dispensed with the pleasantries,

got the credit card out and went to West Marine for components and

cable. $800 later, I had most of what I needed, but still no

inverter. But, we did have enough components to get the

hydraulic/winch system operational.

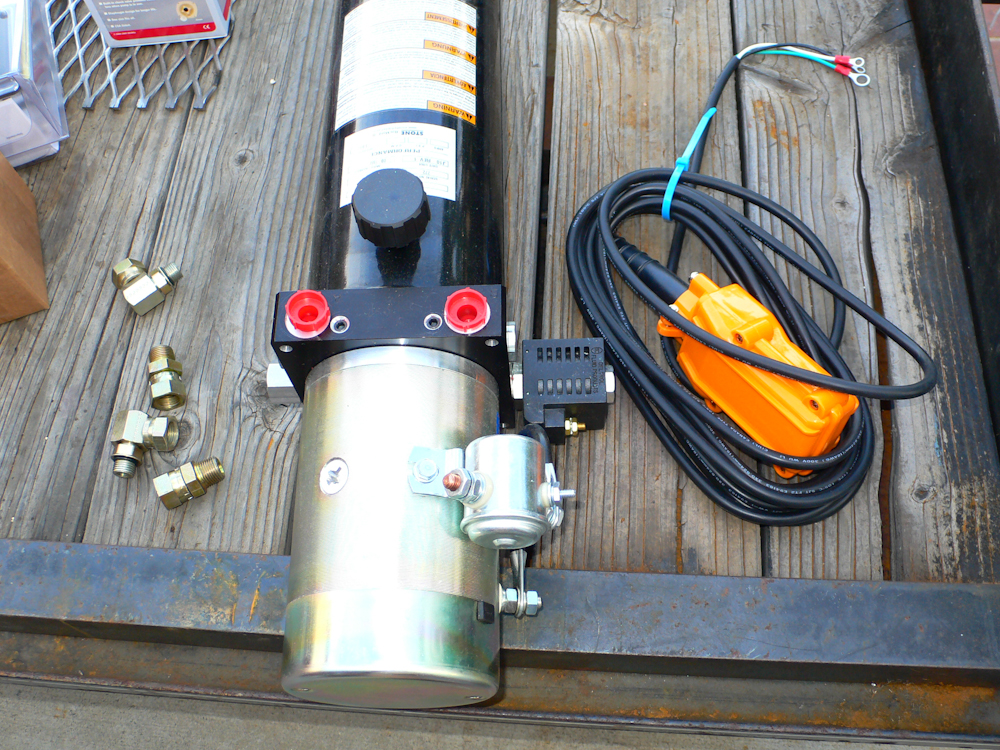

I

had purchased the dual action hydraulic pump system online from an

unknown vendor. The vendor did come through in the end, but

it took weeks for the entire order to be correctly fulfilled.

But, due to my own lack of knowledge about such things, I still needed

fittings, connectors and hoses. These were also ordered online

from various vendors, some known some new. Above is a shot of the

dual action hydraulic pump, reservoir, swivel fittings and the control

dongle. The control dongle would later provide some interesting

entertainment.

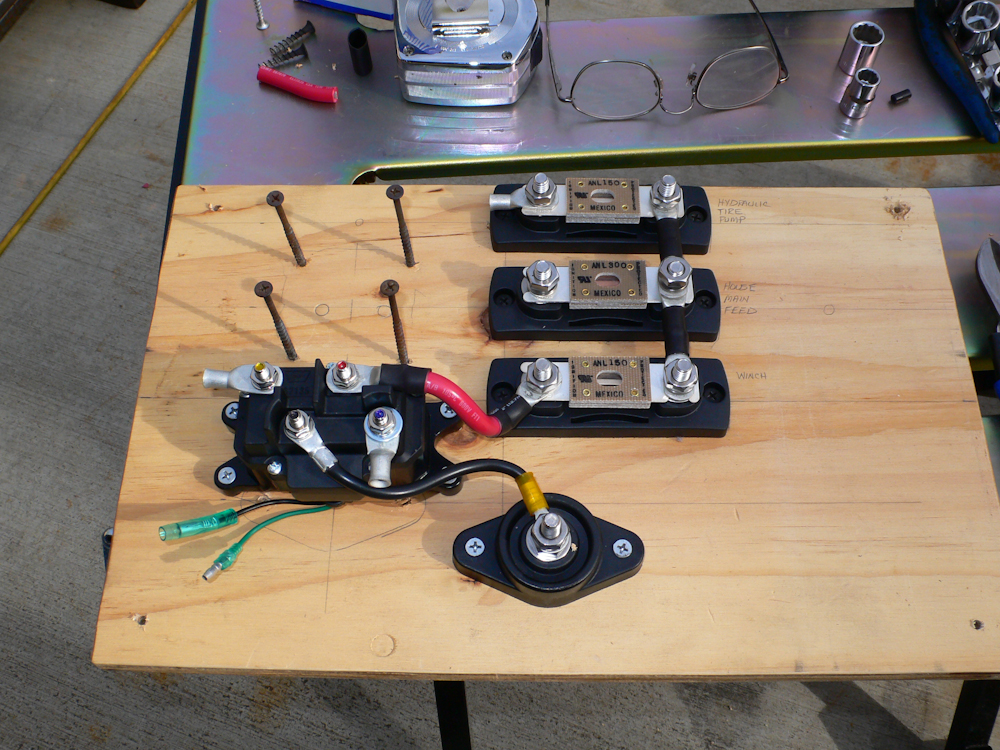

After

testing some preliminary component layouts, I settled on one that would

likely work. Above, the 4 screws are the mounts for the

high-current switch that will connect the house battery array with all

"downstream" consumers. The 3 objects on the right are ANL fuses;

the top and bottom are 150 Amps for the pump and tire lift winch and

the center one is 300 Amps for the house inverter. The object

with the 4 terminals is the winch control solenoid that switches the

current for the winch motor and reverses the polarity if so

commanded. The bottom, odd-shaped item is a PowerPost that is

used to connect multiple terminals. All components were laid out

on plywood and then attached with wood screws for mechanical robustness.

Making

wiring harnesses is both tedious and time-consuming. Since these

were high current harnesses, extra care was given to construction,

routing and encapsulation in loom material to prevent chaffing. I

used #6 marine grade battery cable and it was about $4.50 per

foot. Ouch. The photo above shows the winch fully wired,

but not yet testable. Much wiring must be done before such a test

can be completed.

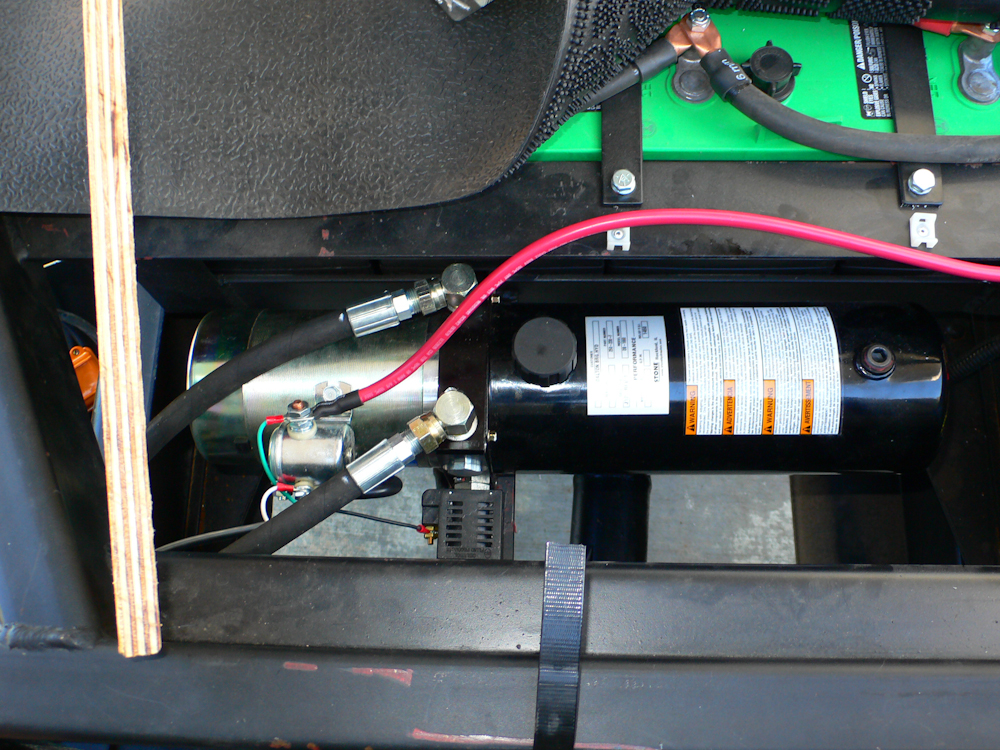

The

hydraulic pump was installed in the mounting frame that Rob had built

from my drawings. Once the pump was bolted down, the hydraulic

hoses were routed, connected and the electrical harnesses were

attached. In the photo above, the red cable is the supply line

for the pump motor. The motor control solenoid is visible (the

metal can at the end of the red cable) as is the direction control

solenoid with the small black wire.

Since

we were trey-careful, the installation worked the first try. But,

working does not mean usable. Specifically, like brakes,

hydraulic systems must have the air bled out before they will work

correctly. After calling my buddy Kai, he suggested mechanically

blocking the system and then running it under pressure while having

connections cracked open a bit. Not unlike bleeding a brake

line. Words really cannot describe the scope of the mess that

this created. True to his suggestion, I had the connections

wrapped with rags, so I did not get sprayed. But, my driveway was

not so lucky. At least a liter of ATF (used as the working fluid)

was lost on the concrete. In the end, this method did not

work. What we finally did, also at Kai's suggestion, was to

remove the cylinder and get the entire assembly below the pump.

Then, we cycled the cylinder several times and the system auto-vented

back into the pump. This only worked because we insured that all

paths forced the air up the hose to the pump. After several

cycles, the cylinder was operating strong without any recoil due to air

bubbles. But, there was another issue. The motor used in

this pump assembly will coast a bit after the current is removed.

The direction control solenoid has no coast: when the current is

removed, the solenoid closes. This curious set of circumstances

resulted in an interesting "whiplash" in the end of the crane boom when

ending a retraction operation. Taken by itself this is visually

interesting, but not a problem. Put a 500 pound load on the

end of 10 feet of extended wire rope and then it becomes a flail.

I needed to do something about this issue.

To

get a better feel for the problem, we extended and retracted the crane

boom. What I noted was that when the boom was extending (away

from the truck) the coast of the motor was benign. You had to

plan ahead, of course, but other than that, no problem.

Retracting the boom was when the whiplash came into play. After a

number of postulated hypotheses, and tests to confirm our conjectures,

we concluded that the real issue was that the control dongle switch had

some kind of issue. I took the switch apart and was able to

convince myself that we could work around the issue. So rather

that stall the whole assembly process, we marched on running wires and

getting them attached to the headboard and frame on their path back to

the control board.

Once

I got all the wiring in place and the connections for the winch in

place, we tested that as well. The winch performed as expected

and we even raised an XM47 tire/wheel combination (about 350 pounds) to

convince ourselves that the assembly would perform as expected.

Of course, to do these tests required me to bypass the balky parts of

the control dongle with a short wire. But, bypass wire

notwithstanding, I was satisfied with the results.

The

entire control board was attached to the camper under the floor as a

temporary setup pending delivery of our tool boxes.

After

the control board was mounted, it was time to attack the switch issues

in earnest. Unbeknownst to me, during the final wiring of the

winch control mechanism, a small bit of stripped insulation had fallen

into the control dongle switch box. When I ran an experiment, the

insulation rolled under the switch connection and prevented it from

disconnecting! Stated differently, when I pushed the button to

engage the pump, the pump continued running even after I removed my

finger from the button. It took a 1/2 a second to realize that

there was a serious issue here and another 1/2 second to reach for the

shorting wire. But, by then, the ram had hit the stop and was

powering on no matter what. I engaged the shorting wire and

caused the cylinder to fully retract, but then had to run around the

truck to the opposite side to turn off the power. As you can see

above, the ram did bend the frame a bit, but it can be bent back.

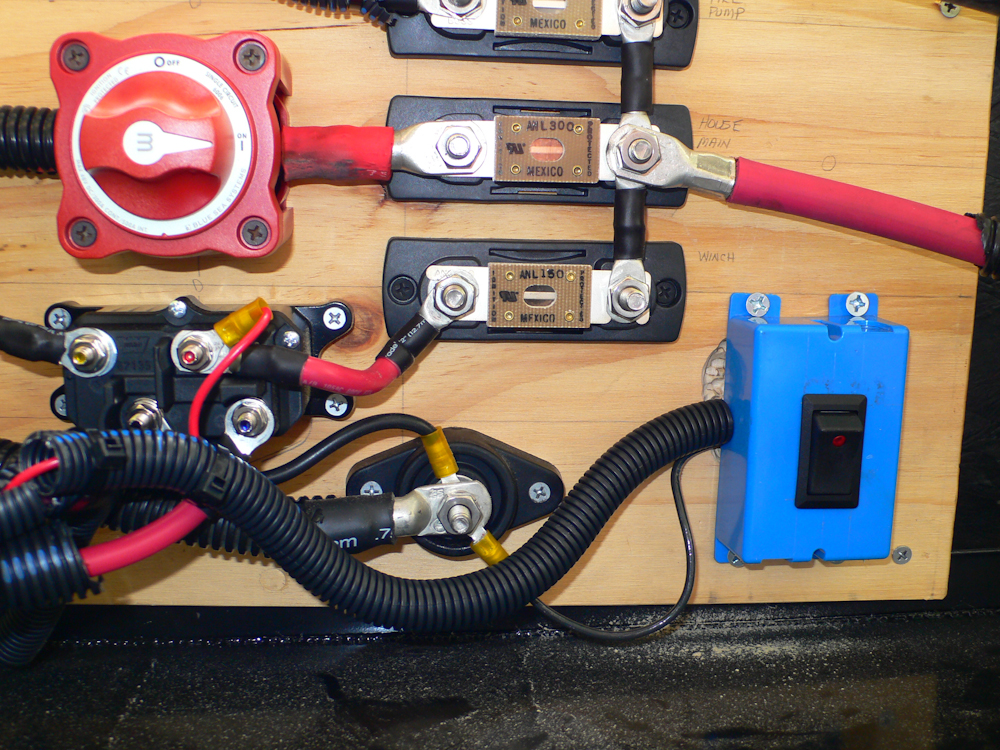

My

response to this interesting, and wholly unanticipated, failure was

several fold. First, the control dongle I purchased would be

pulled out of the circuit and replaced with a unified controller with

several interlocks. Second, an overall system enable switch was

installed in the circuit to prevent anything from coming on unless

commanded to do so. The unified controller got around the

whiplash problem by selecting the direction of the hydraulic pump

independent of the motor control. The coasting of the pump motor

as opposed to the instant response of the solenoid was the cause of the

problem. The solution was to no allow the solenoid to change

positions while the motor in motion. Additionally, the controller

also allowed control of the winch from the same dongle. And, both

functions were disabled by the override switch to prevent the assembly

from engaging unintentionally. In the photo above, the override

switch is in the blue enclosure.

In the process of doing these actions, I got further educated about dealing with online vendors. I did find the inverter/charger unit that I was seeking, but it was quite pricey (about $1K). So, I shopped around and found on for several hundred dollars less from a marine supply store (name withheld). I ordered the unit, but soon realized that the low prices were due to the fact that they never kept any inventory; they just had the unit shipped straight from the factory. So, what should have been a week delivery took 3 weeks. Then, when the unit finally arrived, it was damaged. So, I photographed the damage, contacted the vendor and they stated it would be resolved. UPS did arrived to inspect the package and take it back. In a week and a half, another box came via UPS. It was the same box, with the same damaged components. After several phone calls to unhelpful folks and a few increasingly angry emails, I was able to get an RMA number and return the goods (again).

I have still not obtained my refund, but I am casually optimistic. Only time will tell, but I can assure you that given all the effort I have put into this acquisition, and the cost, they will refund my money or face me in small claims court. Meanwhile, I still do not have my inverter and will likely not take any action until the refund issue resolves itself one way or the other.

Next: 24V -> 12V

conversion for cab electronics and internal camper wiring.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2010, all rights

reserved.

For your enjoyment only, not for commercial use.