The photos below are what we saw.

The

saw required some assembly and as it turns out, some mechanical re-work

as well. This "made-in-China" saw had some mechanical

interference issues that I resolved with a die grinder and a

file. Once the interferences were addressed, I did a test cut to

see if the saw would do what was required. The answer was "yes",

if you were careful.

We

mounted the saw on some steel saw horses and got to work cutting some

2x2x1/4" square tubing to be used in the propane mounting rack.

The saw cut the thick wall tubing without any issues, albeit at a slow

rate.

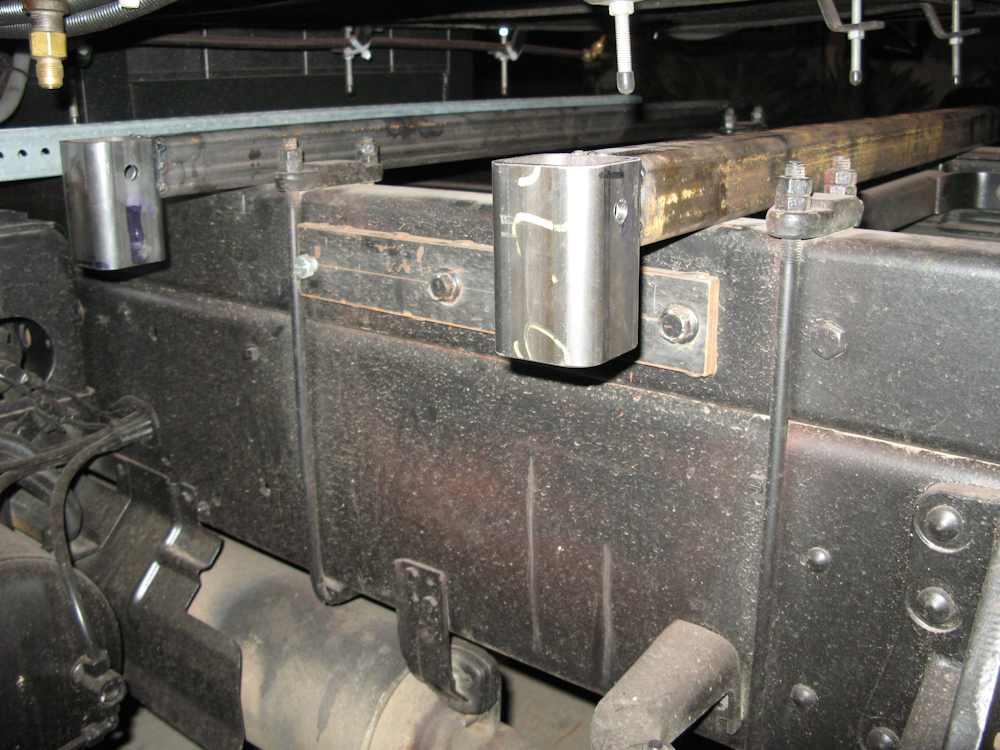

The

main support members were cut from the tubing and were then welded to

the descender support tubes. Above, the members are test fit on

the 1017 frame.

On

my last visit to the steel store, I purchased a 3D corner jig that

should greatly assist in making the corners square. Above,

components of the descender assembly are put in the corner jig prior to

tack-welding.

Once

the descenders were verified to fit as expected, they were "sewn-up"

and hard-welded together. I have been using my trailer as my work

bench as there is no space in my garage. The trailer is a

reasonable substitute for a regular shop unless the weather turns

against you, which it did.

The

descender assembly was welded to the bottom tray and support straps

were added. Above, a support strap is cut after welding.

The

cut area is ground smooth prior to welding the exposed edge.

The

finished rack ready to be painted.

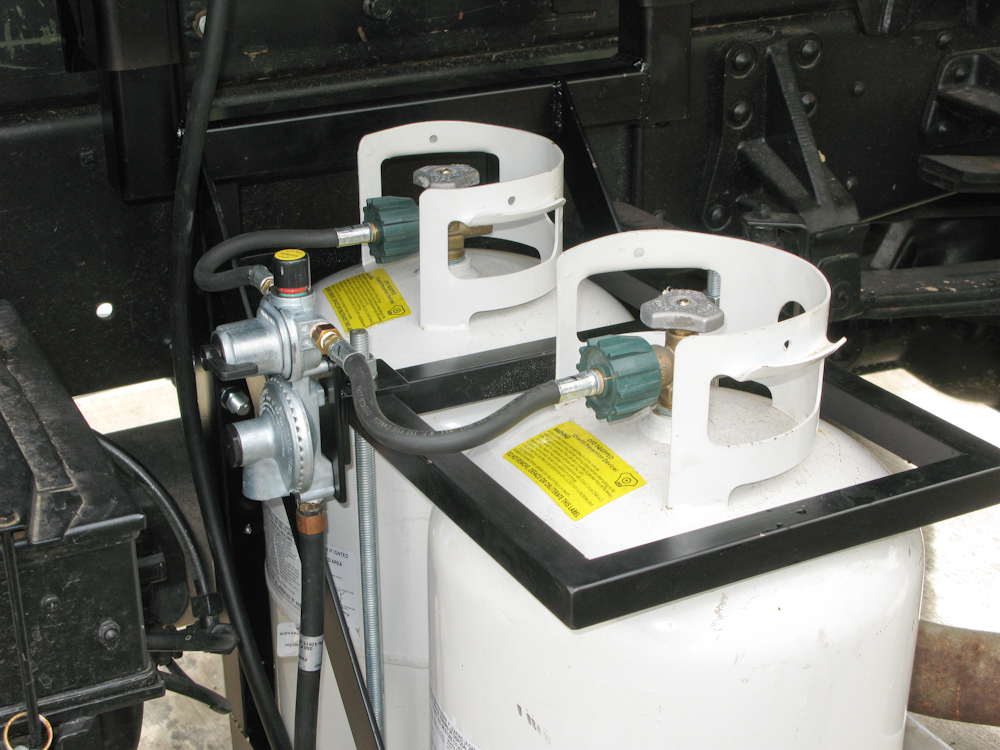

With

propane bottles and the top, the mounting geometry becomes

clearer. The asymmetry is due to required clearance from existing

components on the 1017.

The

top frame members were reinforced with 1/4" gussets and mounting tabs

were added. When the welding was completed, Kathleen took them to

the "paint shop" in the back yard.

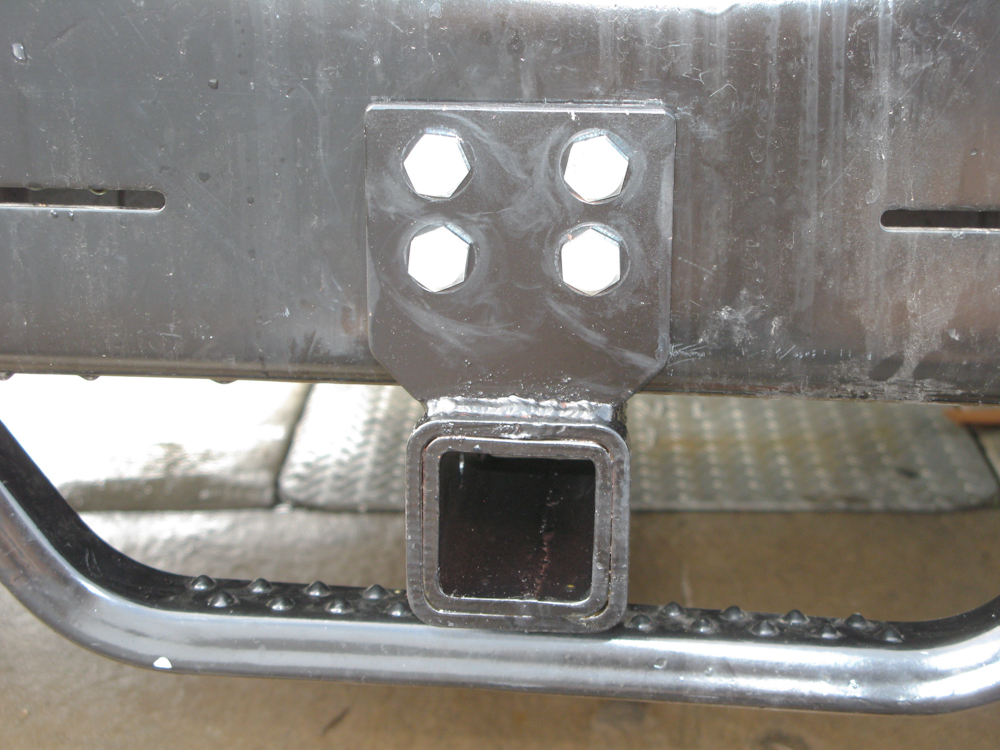

The

front trailer hitch needed to be beefed-up, so a 4"x4" plate was added

to spread the load over the front face of the bumper.

After

the mounting frame members were painted and installed, heat shields

were added to the outside of the frame using polished diamond plate.

The

reason for the asymmetry in the descender frame becomes apparent in the

photo above. We had to design around the mounting hanger for the

exhaust to make use of the available space.

Once

the paint on the front hitch was dry it was re-installed on the front

bumper.

A

mounting plate for the propane regulator was fabricated, painted and

installed.

Details

of the regulator mounting can be seen in the photo above.

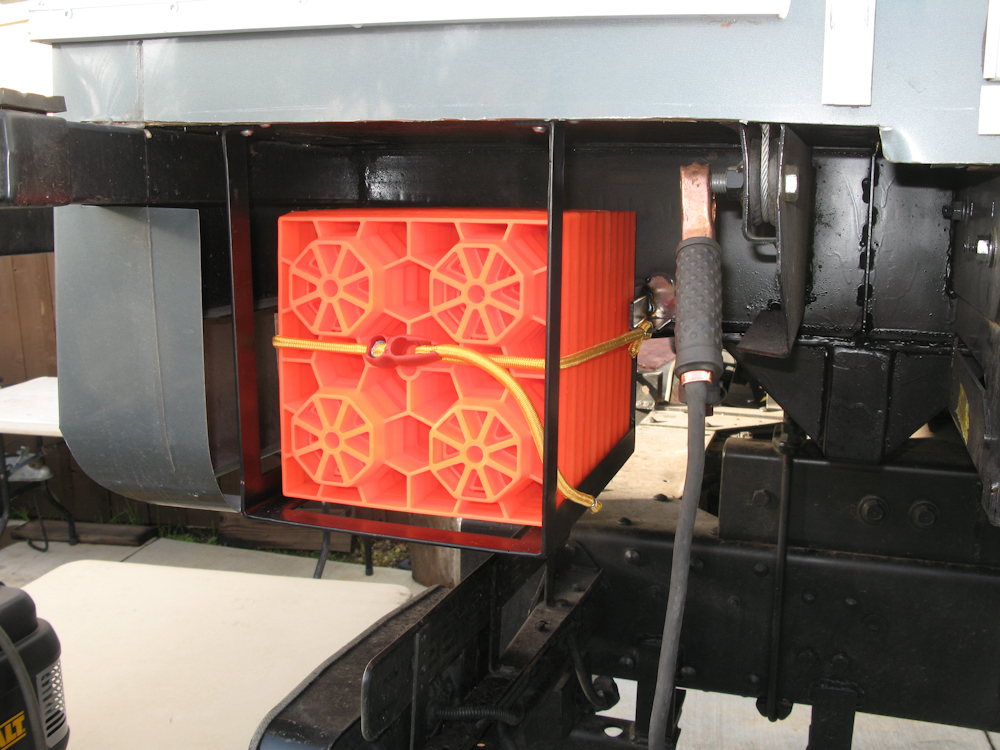

Mounting

frames for our leveling blocks were fabricated and painted.

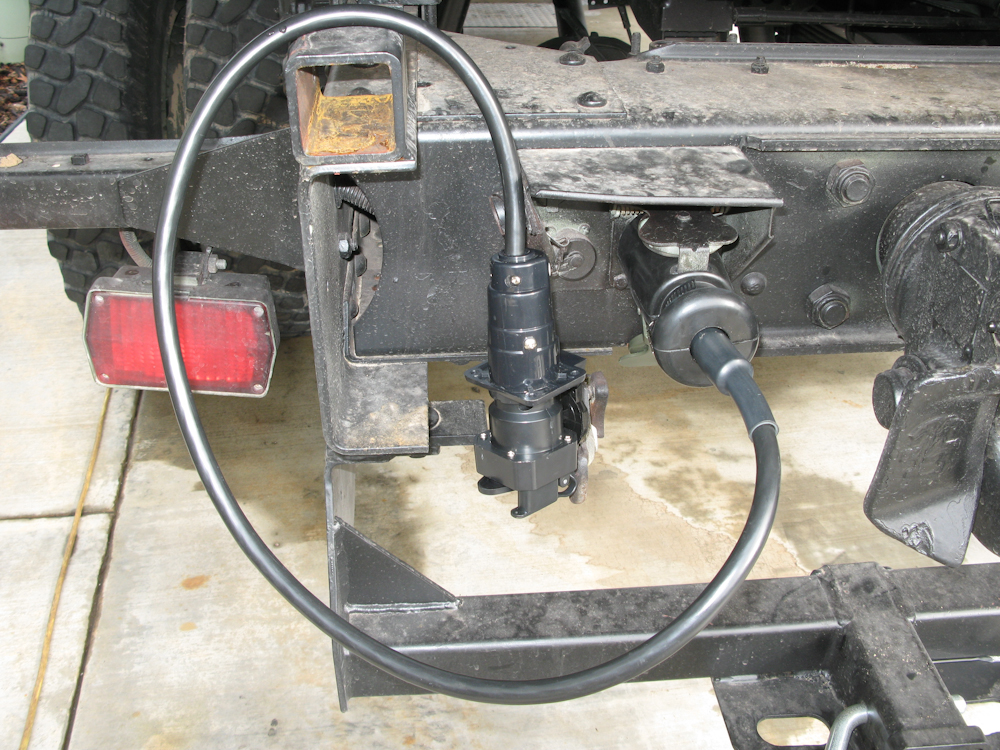

Amazingly,

online I found an adapter that maps a 24-pin NATO trailer hitch to a

7-blade RV connector. At NAPA, I found an adapter that maps

7-blade RV to both 6-pin and 4-pin trailer connectors. I will,

however, have to change the lighting on the trailer to LEDs that can

tolerate the 24 volts that the 1017 uses.

The

leveling block frames were welded to the trailer and an appropriate

shock-cord restraint was made.

The

front frame was welded next to the mounting rack for the stairs.

This was a ton of

work. We faced a number of challenges including rain on our

outdoor workshop. The saw made things easier, but in retrospect,

I should have anticipated the need for a saw and gotten a

higher-quality saw. This saw works, but has some annoying

issues. Next up: internal plumbing in the living quarters and

electrical retrofit.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2010, all rights

reserved.

For your enjoyment only, not for commercial use.