By

2017 Thor had accumulated a bit over 70km under my

ownership. We do regular maintenance on the truck, but

sometimes lack of use is worse treatment than hard use. In

this case, I had taken a consulting gig that prevented our travel

for nearly a year. During that time, the truck sat in my

driveway slowly eating itself. I had purchased an Engel

cooler to be installed in our center tool box to provide cold

beverages and ice during trip. The installation spanned

months as the consulting gig kept eating up my spare time.

When the mechanical installation was complete, we attempted to run

electrical to the unit and discovered that the voltages were

low. During subsequent investigations, we discovered a set

of interconnected issues.

We

were preparing for a summer road trip and discovered a multitude

of problems had occurred during Thor's extended vacation. To

meet our goal of seeing the solar eclipse from the path of

totality, we needed to get our repairs in motion. We tried

to start the truck and discovered that the starter had developed a

hitch. Having never removed a starter, it looked like a big

job. And it was. Not because the removal was

difficult, but rather it was clearing a path to the starter that

was difficult.

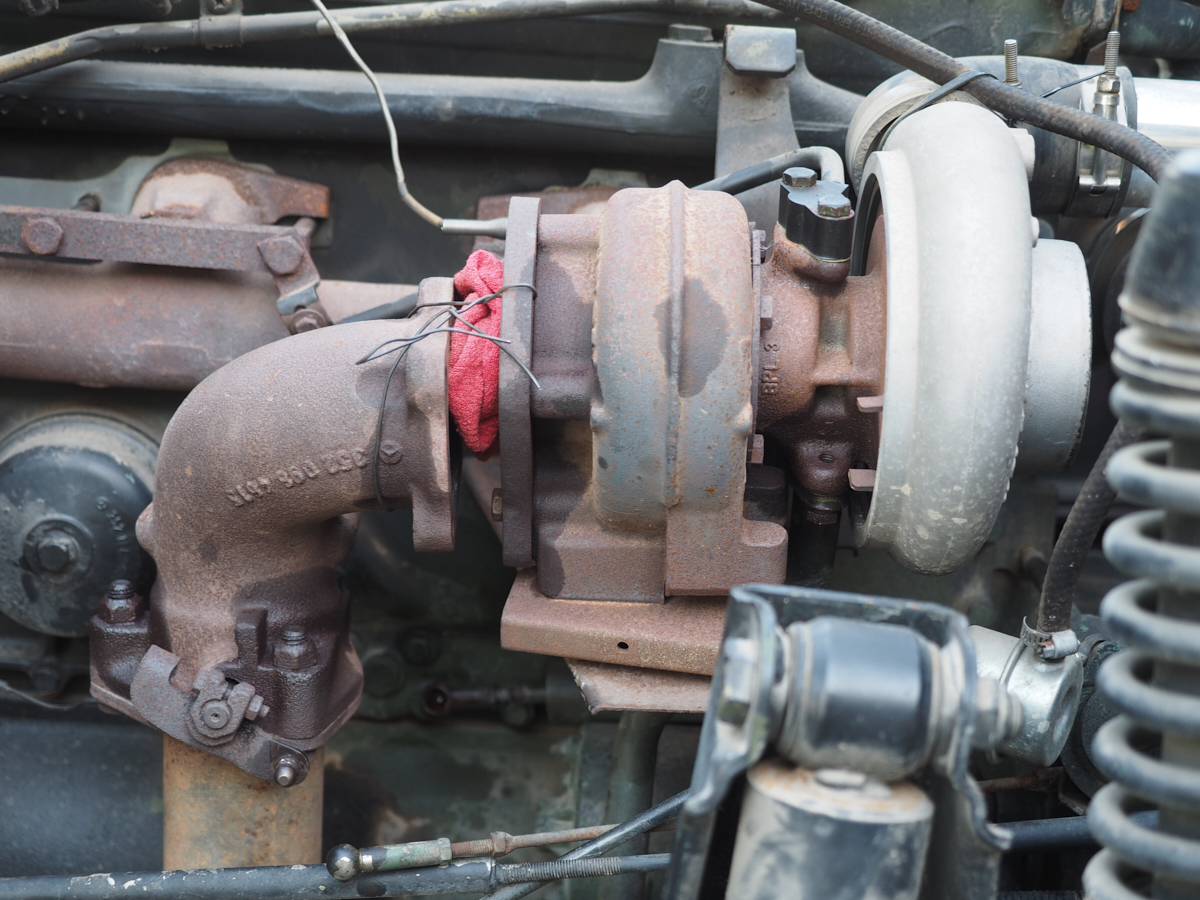

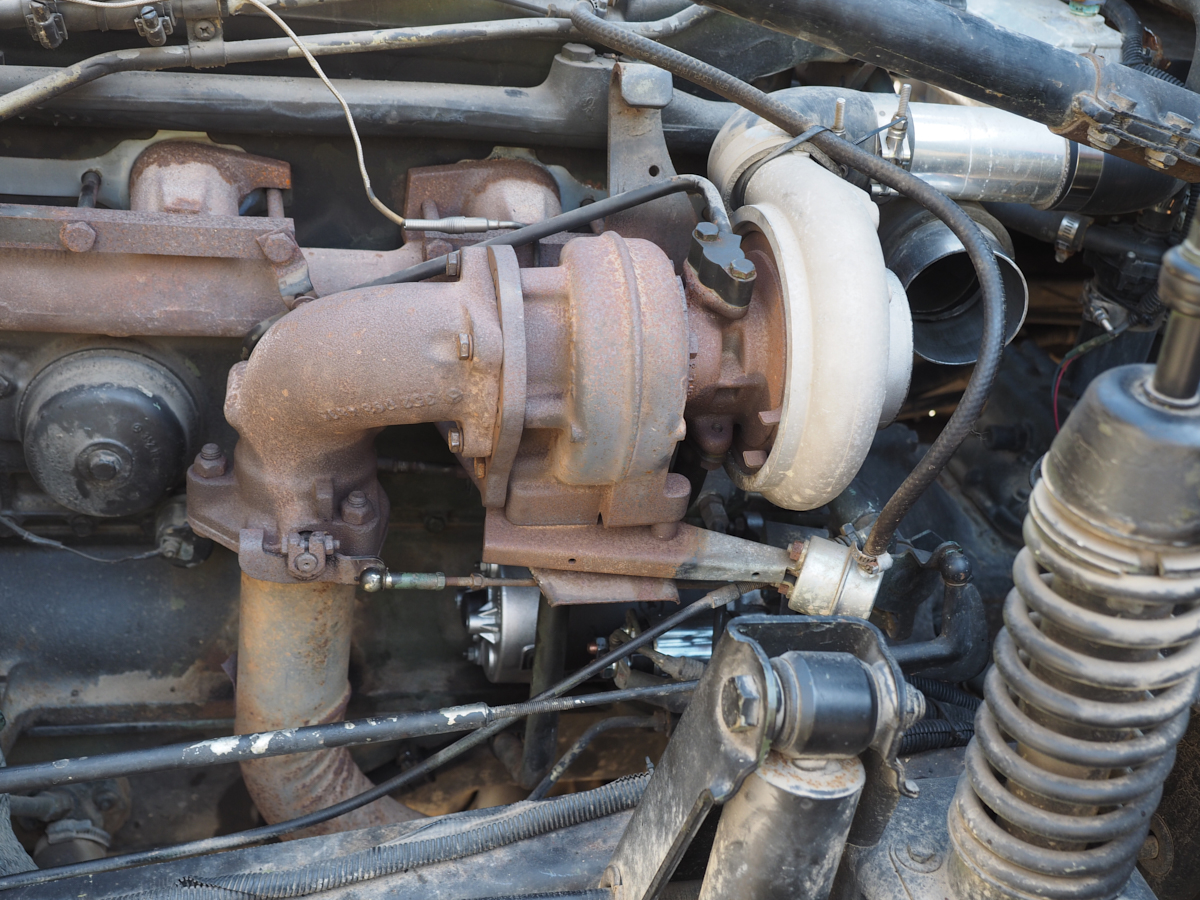

After

staring at the tight working conditions, I concluded that the only

way to access the starter was by removing some exhaust plumbing,

linkages and the turbocharger return oil line. Above, the

exhaust line was removed from the turbo. Fortunately, our

recent turbo service left some non-corroded bolts that allowed an

easy removal.

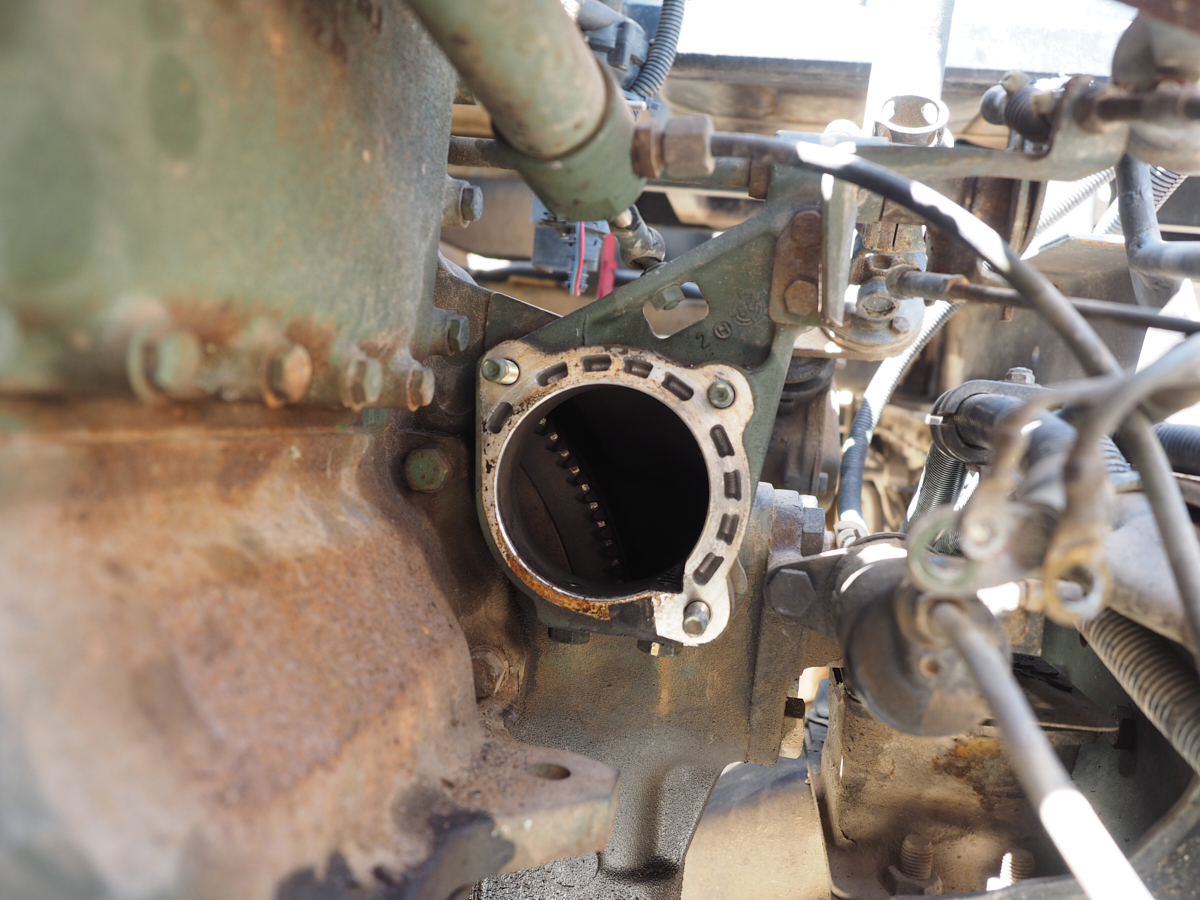

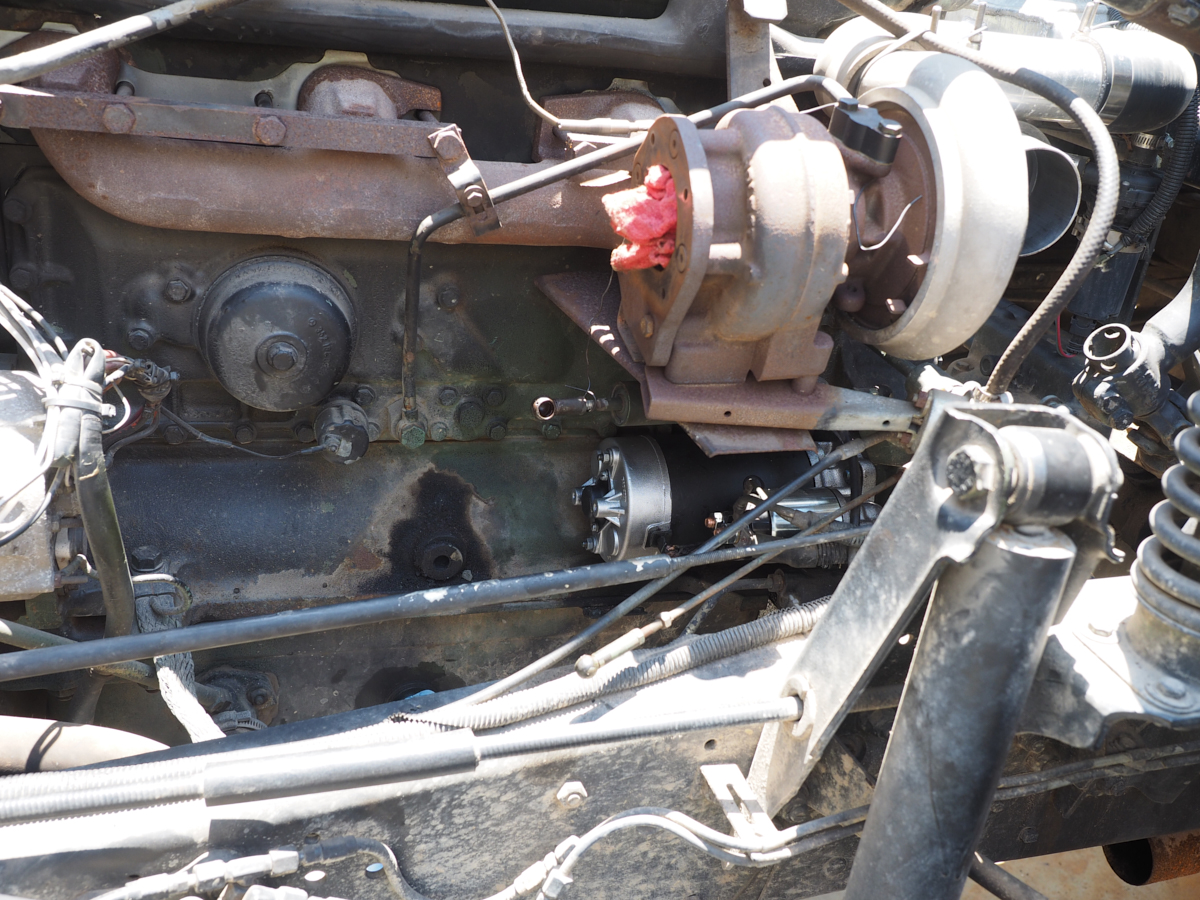

Several

linkages have been removed as well as the exhaust line to allow

viewing the starter.

The

access to the bolts that held the starter in was occluded.

The biggest issue was there was no "straight shot" from the

outside world that would allow putting a socket on the nuts.

In the end, I ground a socket that allowed access skirting the

shoulder of the starter. Add in a wobbly extension and we

were in business.

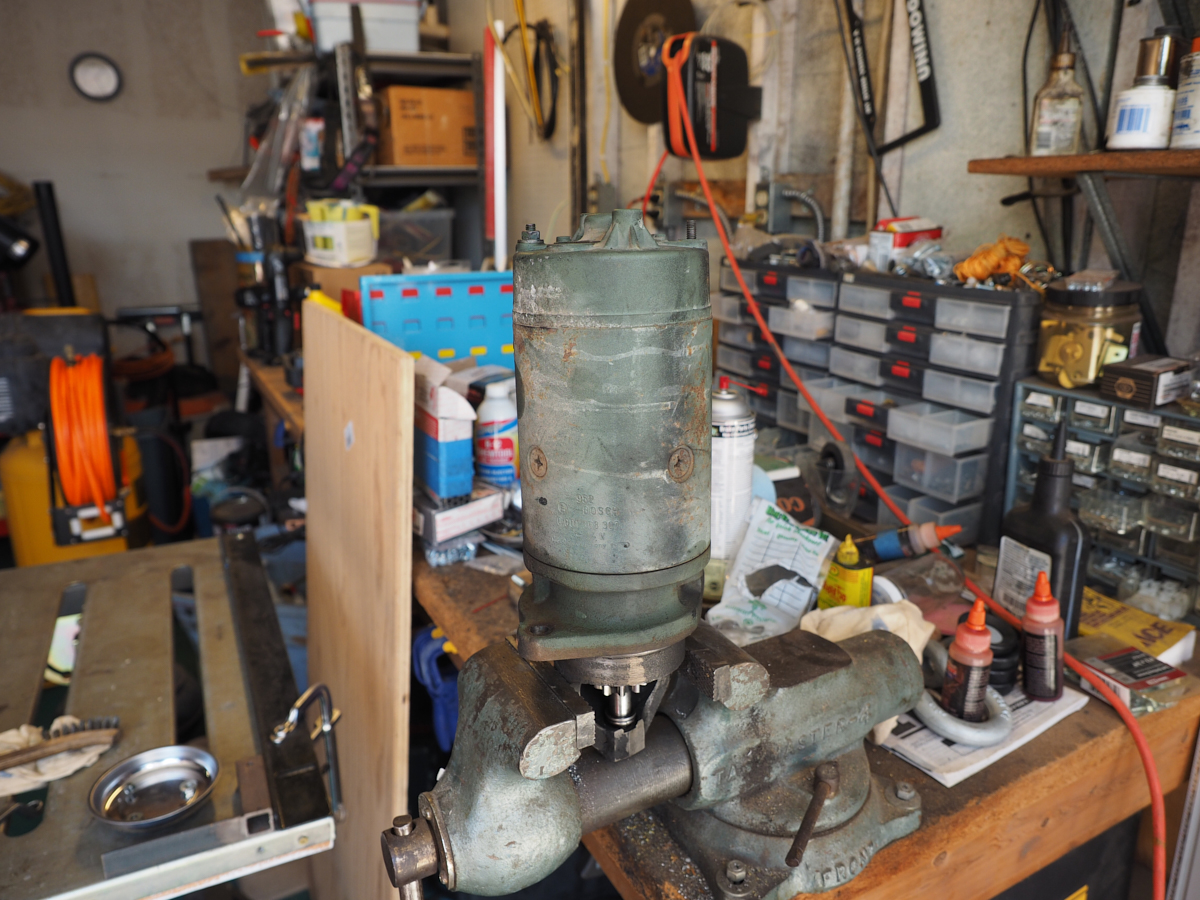

The

mounting points looked quite clean.

The

starter is a big chunk of meat.

Doing

some web-work, I discovered that I could examine the brush cup of

the starter. I mounted it in the vice and tore into it.

The

shaft protection cup.

Stator

housing removed showing the rotor. It was in good

shape. It turned out that the solenoid was the issue.

Rebuilt

and clean, it was only $150 to get repaired (and several days).

Rebuilt

unit installed.

All

the parts put back in place.

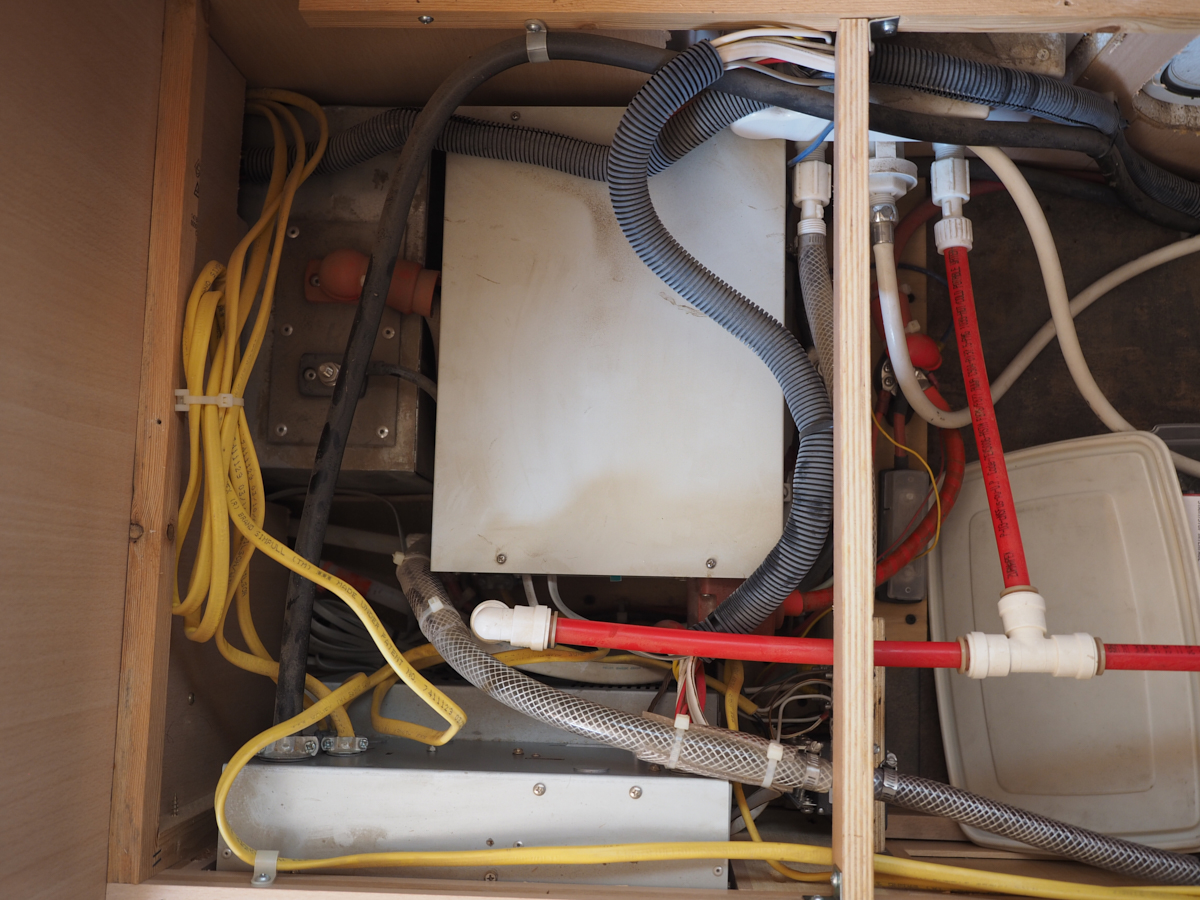

Next

up were the truck batteries. I had installed a multi-channel

marine charge maintainer on my battery array, but since the issue

was with the Xantrex controller, the charge maintainer had no

shore power, thus allowing the batteries to be damaged.

Heavy, awkward and expensive, the batteries were simple to

replace.

The overall source of the problem was the box in the center of the frame above - thet Xantrex inverter/charger. As you can see, I outdid myself during installation, packing components tight into the available space. Removal was a hassle, but we finally were able to get access to the unit without a full removal.

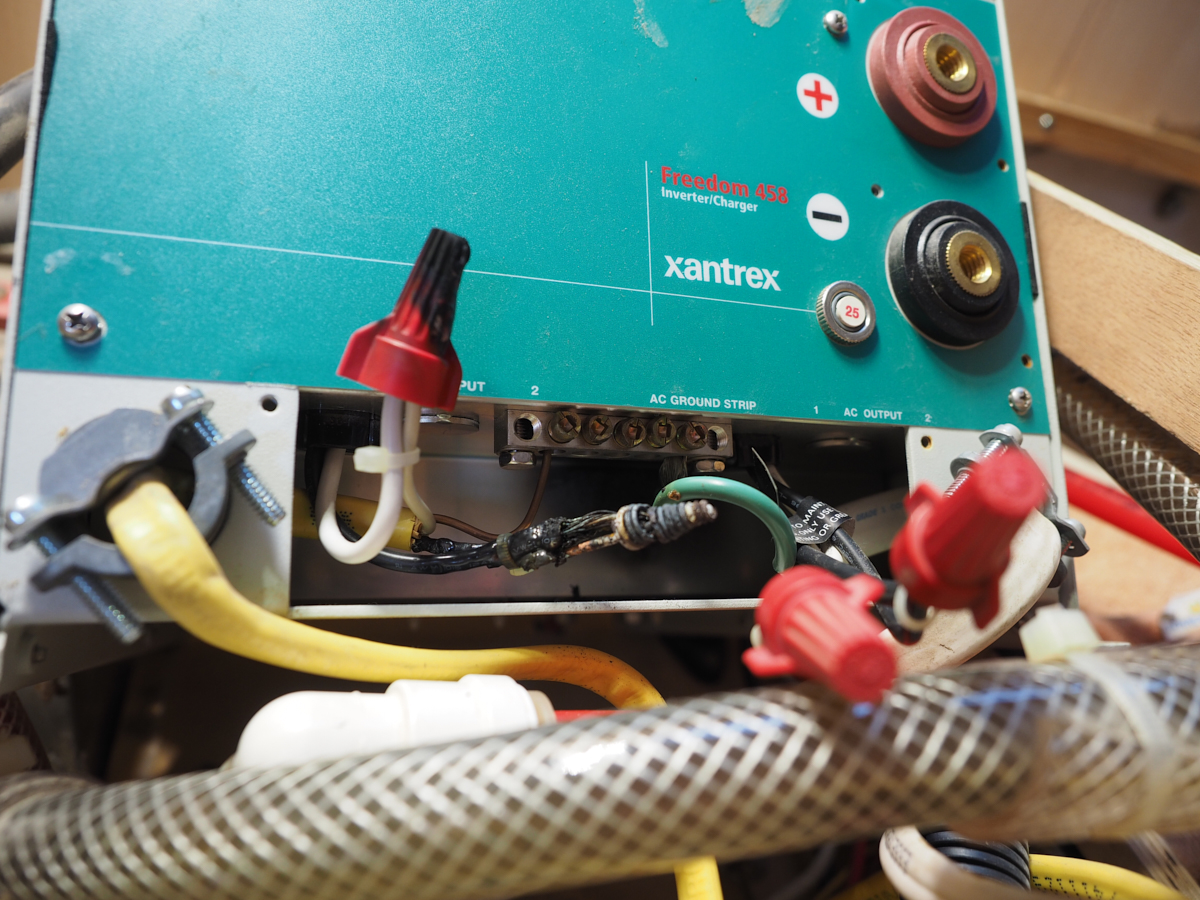

Oops,

there is a problem here. A simple visual inspection showed

the likely cause of the issues.

For

whatever reason, the hot side of the input line had become a high

resistance connection and started on fire. The issue went no

further than the junction box. We are not sure when this

happened, but there was never the smell of smoke in the

cabin. Happily, when the bad wire was removed and low

resistance crimped connections were used, the unit came back to

life and was performing correctly. After opening access to

the guts of the system, I concluded that given the electrical load

of the Engel, it was time to finally install solar on the

roof. Once that task was completed, the truck should be

fully self sufficient.

Back

to the original task - installing the Engel cooler. We had

installed industrial drawer slides inside the tool box years ago

and they served us well carrying our Yeti ice box. We were

lucky enough to have the same mechanical setup work for the

Engel. Almost. The Engel cooler was deeper than the

Yeti and needed a bit of help to prevent a mechanical

interference.

A

second set of drawer slides were required to allow the Engel to

open without interference. These locking slides were

installed flat due to space restrictions.

The

Engel is a nice unit and fits within the existing

infrastructure. We may need to add vents to the tool box,

but we are going to run it for awhile to see.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2017, all rights

reserved.

For your enjoyment only, not for commercial use.