The photos below are what we saw.

After the frame articulation test

shown in Part 3, our plan was to remove the camper, and then complete

the sub-frame fabrication. Above, Rob positions the fork lift to

raise the camper.

The camper was then placed on jack

stands for sub-frame modifications and other actions.

The articulation test showed that

a mechanical interference was likely under extreme articulation.

So, rather than risk tweaking something, we decided to trim the

sub-frame to provide additional clearance. Above, the chalk lines

show where the plasma torch will cut the frame.

The center frame member needed a

bunch of additional welding done to complete the fabrication.

The tack welds on the center frame

member would have to be hard welded before priming and painting.

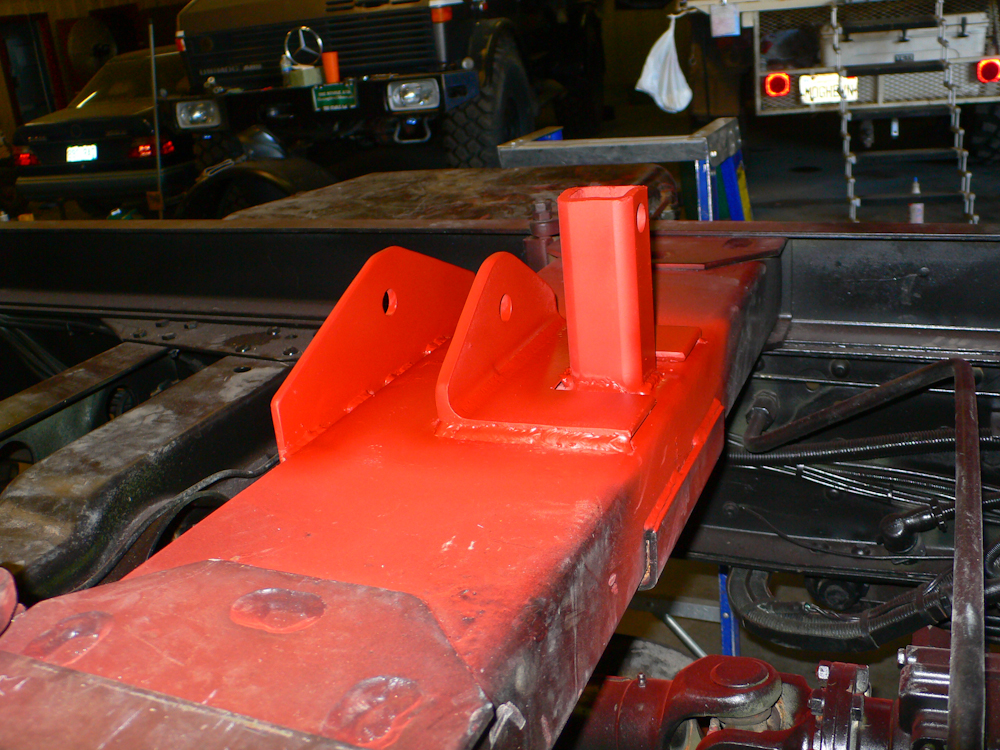

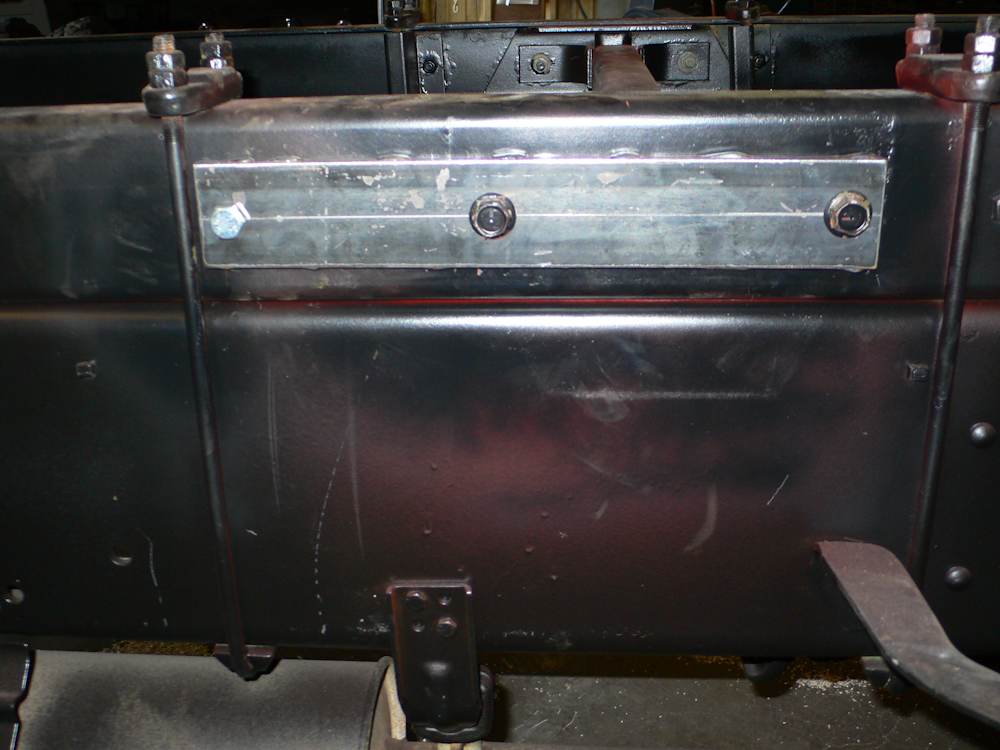

The truck frame attachments were

good as-is, so they were primed and painted.

The rear frame attachment was

primed and painted as well.

Kathleen used an air buffer to

remove surface rust and scale prior to priming the center frame member.

The rear member still needed some

welding done to box the frame.

The rear frame member was

left-right asymmetrical to provide clearance for the gray water

plumbing. It was boxed as well.

Rob found a spare Class III hitch

to mount on the truck. We used 3/8"x5" angle as the mounts.

The hitch was tweaked by use from

the previous owner, so we straightened it as best we could and then

welded in gussets to prevent further deformation. Once completed,

the hitch was attached with Grade 8 bolts and LocTite blue.

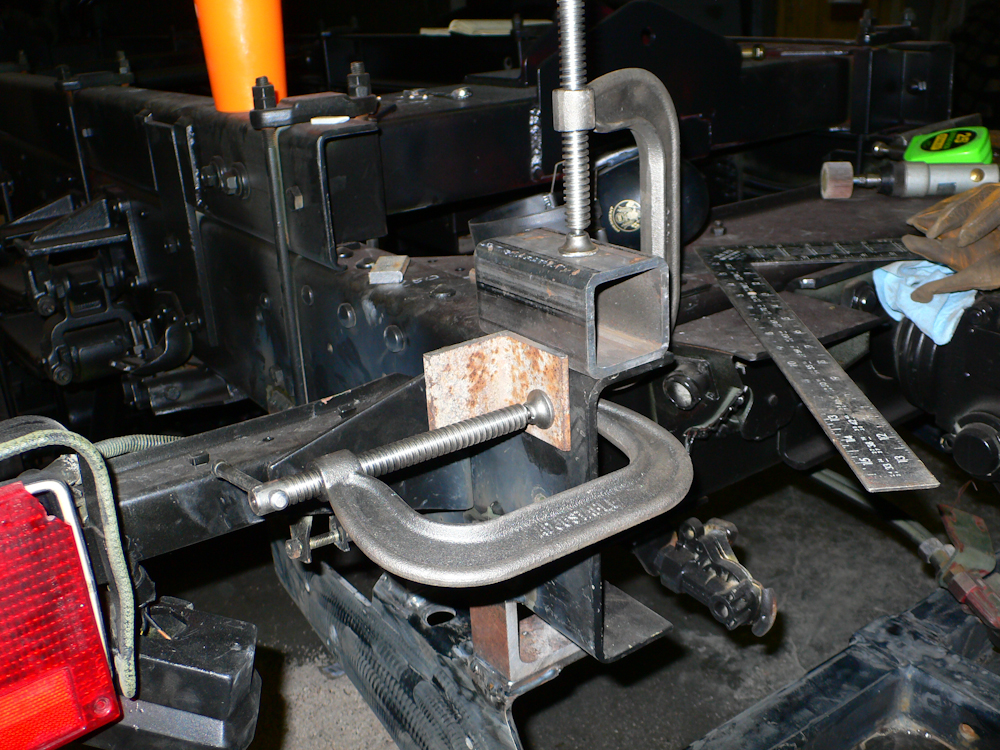

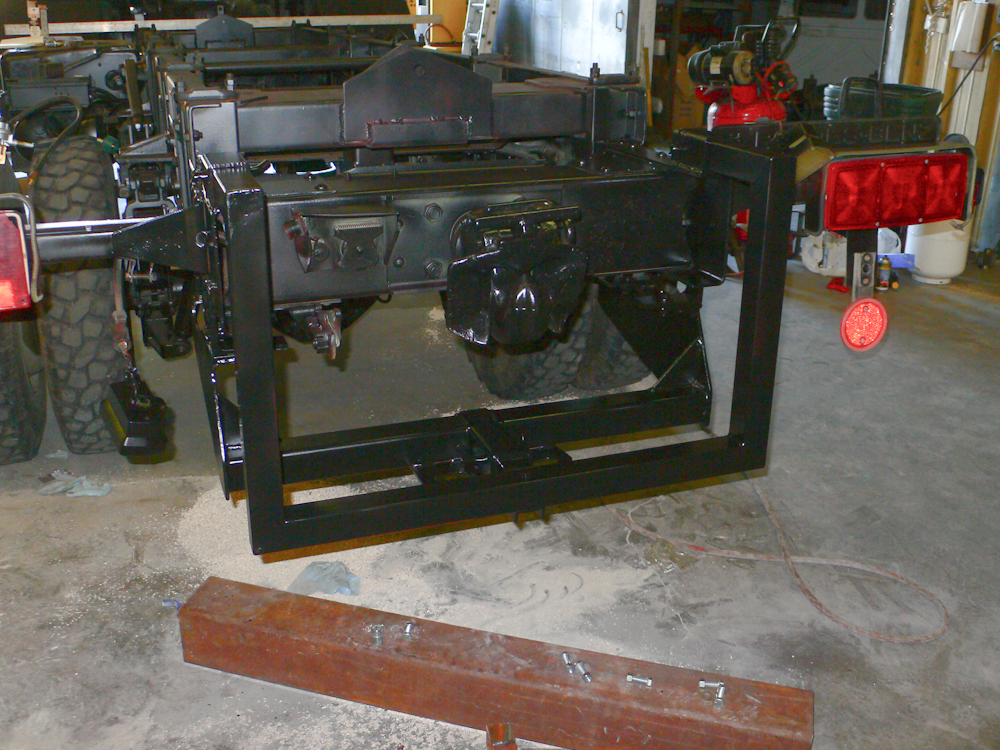

Next, Kathleen and I attacked the

removable cargo basket mount. The plan was to weld 2 trailer

receivers on the top of the frame members and then plug the frame into

them. The bottom of the frame would be supported by an insert

that goes into the main trailer receiver. Above, we get the

receivers true on the frame prior to tacking.

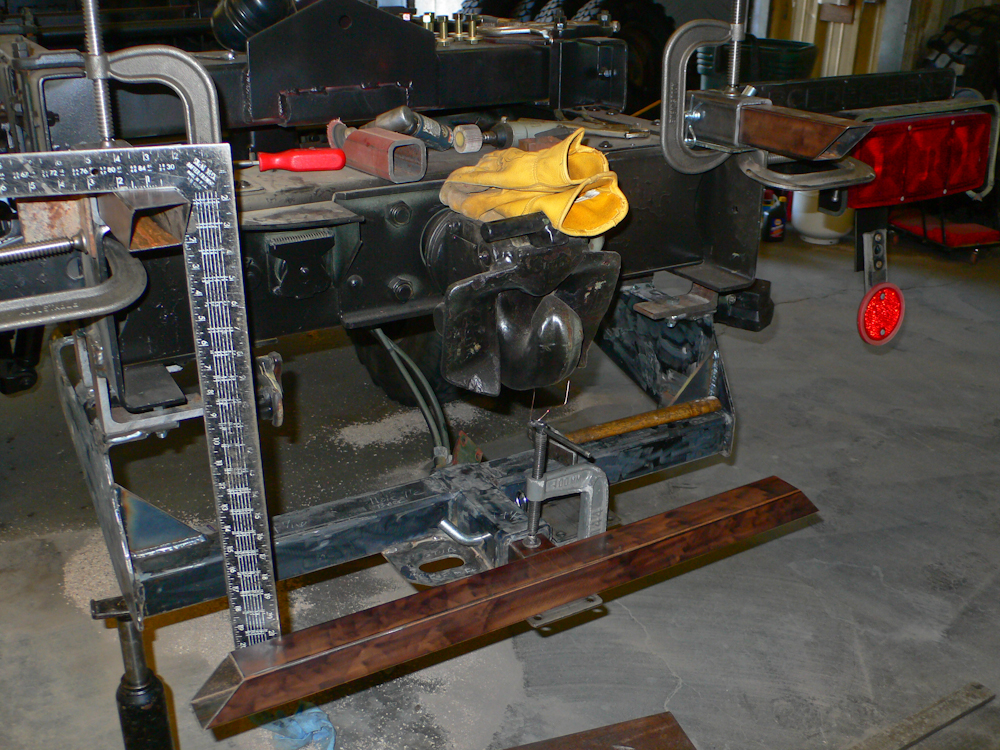

All corners on the basket frame

were mitered cuts, so careful layout and cutting were required to get

them to fit and be square. Above, you can see the lower member

bolted onto the trailer hitch receiver.

We measured and adjusted multiple

times until we were sure it was correct.

Our diligence paid

off; the frame was square and true on the first try.

Rob started on the fabrication of

the house battery box. This box was constructed out of 3/16'

material and needed to hold nearly 300# of lead-acid batteries.

Above, Rob

completed grinding after boxing the frame.

The front pivot mount is completed.

To mount the propane, we decided

to co-opt existing holes in the frame.

The battery box and battery

retainer straps were completed and awaiting painting.

The roof lift hydraulic pump was

moved to the wheel well of the trailer and the pressure and return

lines were moved to the new location.

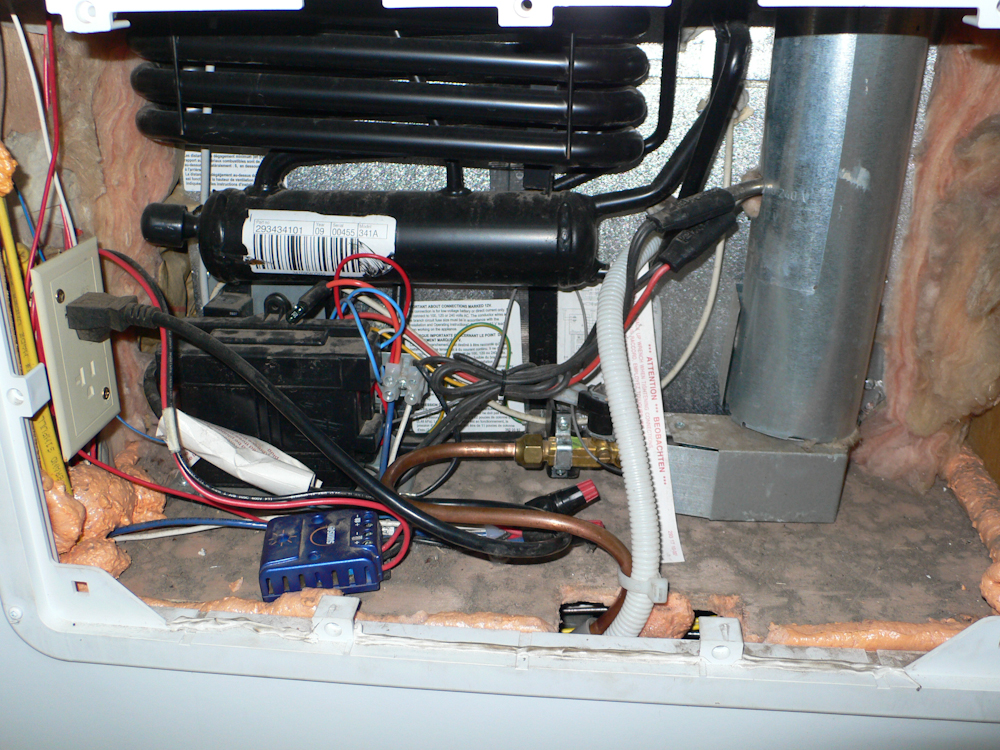

The propane feed lines were

modified and the lines to the refrigerator were moved. The drain

line from the refrigerator was moved as well.

Kathleen prepped, primed and

painted the front mount and battery box.

The extra strap on the battery box

is the mounting for the tire hydraulic pump.

When the battery box was

completed, Rob moved on to the tire mount/headboard.

I designed an access ladder and

fuel can rack to go on the driver's side of the headboard. On top

of the can rack, the generator will be mounted.

I purchased the generator on a day

trip to Pueblo. Above, you can see how the generator will sit on

the can rack.

The rubber feet of the generator

sit in the circular cups.

The cargo basket rack was

cosmetically completed and painted.

A view of the completed battery

box with 4 golf cart batteries installed awaiting wiring.

This was a lot of work that spanned many

days. We addressed some difficult geometry issues, but in the end

always came up with an adequate solution. Next, the camper will

be re-mounted on the truck for "final" attachment.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text

Copyright Bill Caid 2010, all rights reserved.

For your enjoyment only, not for commercial use.