We had several down days

while Rob was attending to family matters with his new twins.

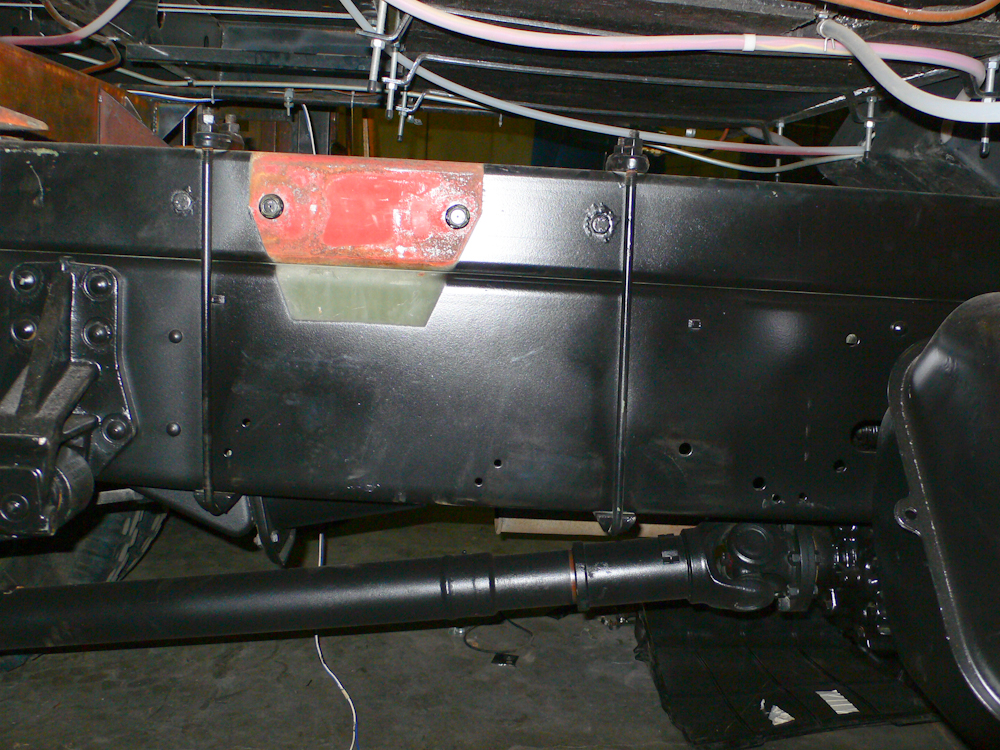

When we started work again, the objective was to attach the frame

members to the frame and perform a frame articulation test.

The photos below are what we saw.

The original red factory

primer can be seen where the original bed mounting bracket had been

before it was relocated rearward about 2 feet. The resulting

space will be used for mounting a frame to hold 2 30# propane

bottles. Unlike the Alaskan camper, this camper has a much bigger

appetite for propane due to the refrigerator, water heater, forced air

space heater and cook top/oven. And, I may add a catalytic heater

as well.

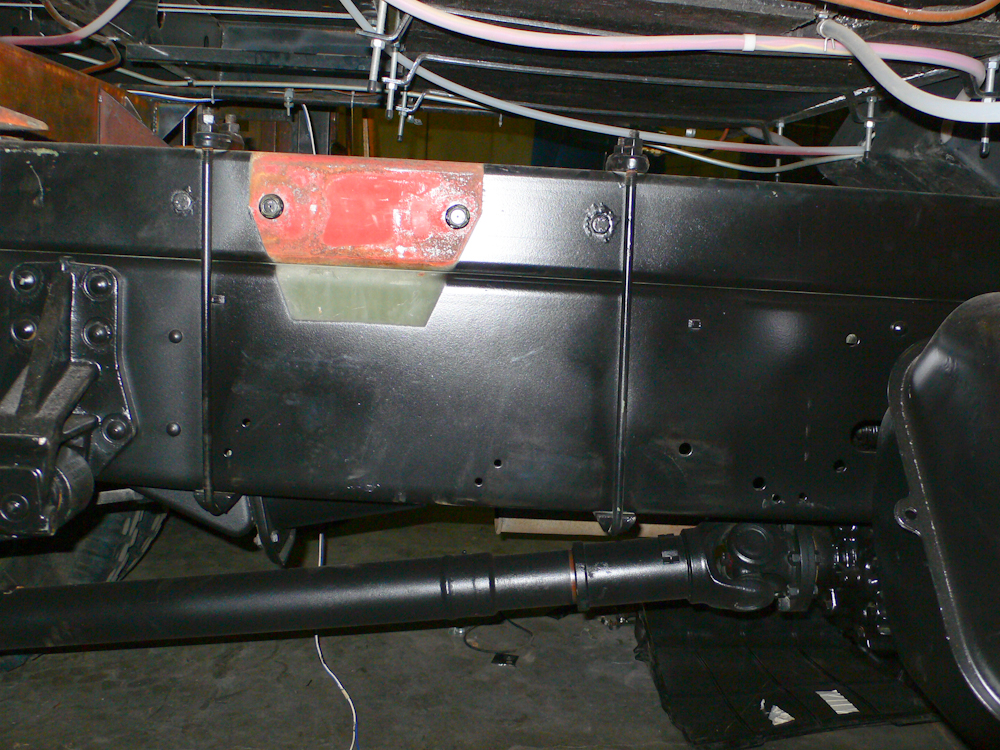

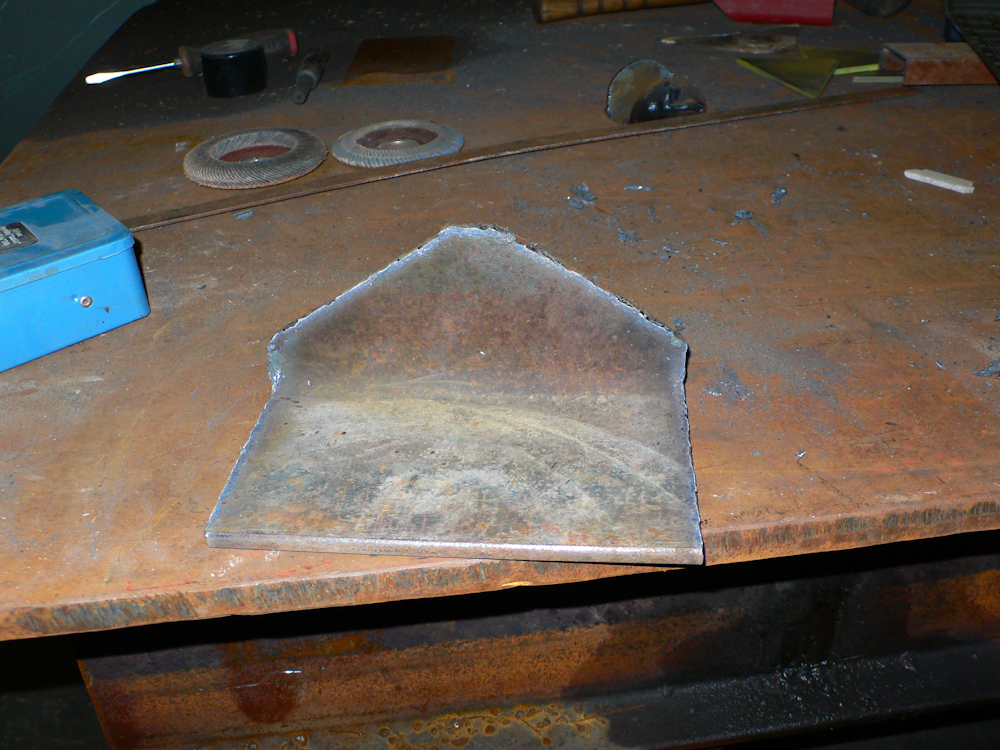

The camper had sat on the

truck over the weekend and we had plenty of time to measure things

required for attachment of the pivot points. In the end, due to

flexure in the camper body itself, we elected to increase the offset

from the frame by 1/4" and add 3/8" support shims to the hard

mount. The reason was that frame flex was causing the side door

to be out of plumb. The mounting bracket above was being cut out

of 3/8" 6 " angle iron.

The other half of the mounting "ear" was made out of 1/4" plate.

The hydraulic lift pump

used to raise the top was removed from the tongue area and set aside

during the welding to provide needed access. In the end, the pump

assembly will be relocated over the driver's side rear wheel very close

to where it is currently sitting.

The hydraulic lift pump

was moved from the tongue area to provide room for the 250# of lead

acid batteries that will power the camper. The battery tray will

be in the open area between the frame rails in the photo above.

The front vertical pivot

ear was welded onto an existing frame member.

The thicker angle bracket

was also welded to the same member next to the support for the spare

tire rack.

When the pivot bolt was

installed in front pivot and the supports for the rear pivot were

removed, there was about 7/16" of "float" on the rear frame

member. Our objective was 1/2", so this was very, very

close. We shimmed the rear to the desired 1/2" and then welded

the vertical ear onto the rear cross member. In the photo

above, you can see where the paint has been removed in anticipation of

welding.

The front and rear pivots

were welded to the frame cross members. The center "hard mount"

was not yet welded, but rather just clamped to the main I beams of the

trailer. We were confident in the mounting, so we decided to

perform an articulation test to insure that our mounting strategy was

correct and that there would be adequate clearance. The plan was

to use the fork lifts to elevate opposite corners of the truck and see

what happens with respect to articulation of the frame rails of the

truck relative to the camper frame. Above, the forks of the fork

lift were positioned around the tire prior to the lifting.

As the rear tire is

lifted, you can see the truck frame rails twist. The camper

mounting frame is staying relatively level, at least so far. This

lift was only about 7".

As the lift height

increased, you can see the camper start to tilt. Note that the

roof of the camper is elevated and would never be elevated for travel

unless there were an emergency or a mechanical failure.

As the opposing front

wheel was lifted, you start to see substantial articulation in the

frame. Above, note that the red frame (tire mount) is also a

3-point design but is hard mounted close to the rear end of the

cab. The brown, rust colored beam is part of the camper frame and

is also a 3-point mount, but with a longer distance between the hard

mount and the pivot point.

The front wheel is about

20" off the ground at this point.

The end of the frame rail

is getting pretty close to the cross member. I did a set of

calculations to determine when the contact would occur and the

theoretical vs. empirical difference was quite small.

As the lift height

increased the flexure angles increased as well.

The photo above is about

22" of lift on the front and about 10" on the back. The rear fork

lift had hydraulic seal issues which prevented the height from being

constant due to seepage.

It looks scary, but it is

only about 12 degrees of slope.

The camper frame was

measured at 5 degrees of slope, nearly constant from front to back of

the frame while the truck slope was about 12 degrees.

| Previous Adventure | ||

| Trip Home Page |

Photos

and Text Copyright Bill Caid 2010, all rights reserved.

For your enjoyment only, not for commercial use.