This

part of the fabrication experience was filled with detailed design and

careful construction. We completed the spare tire rack, generator

mounts, can rack and a host of other important, but small tasks.

The photos below are what we saw.

We

managed to melt an air line with our welding. The truck sat in

the shop for several days until we got around to fixing it. But,

Rob had the right parts and once the leak was located, the fix only

took 5 minutes. Once the truck was rolling, we took it to the

local scale to get a weight: about 11,500 pounds naked.

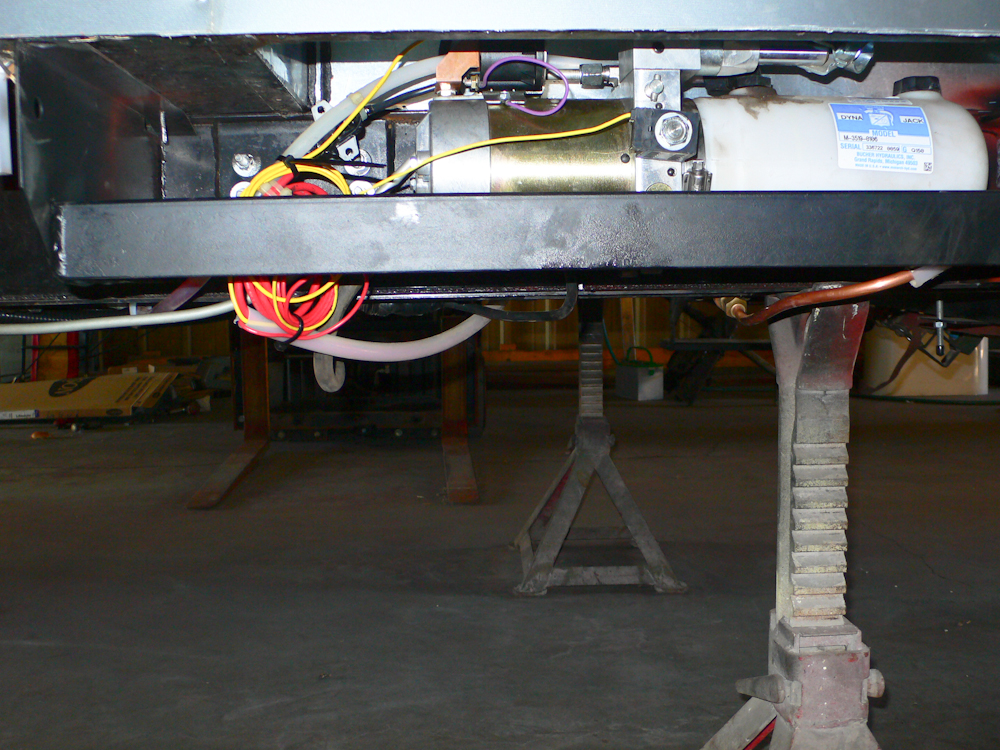

The

roof lift pump was wired with 2-0 cable due to the current draw and the

long run from the battery array.

Once

the wiring actions were completed, we lifted the house back onto the

truck.

The

fit was tight, but it was supposed to be that way. It took us 15

minutes of shifting things around until it was correctly alligned.

The

massive front mount was a bit harder due to get alligned, but diligence

won in the end.

Once

the house was on the frame and the frame was squared up, we prepared to

weld the shims into place. In the photo above, the shims are the

3/8" bar stock that is not painted.

The

house is now fully seated on the frame and all parts are alligned and

awaiting final welding.

The

first stop was for fuel. The tank was bone dry, but we knew that

the tank would be replaced in a few days, so I only got 5

gallons. We took the rig for a 20 mile drive south of La Junta

and things worked fine. At the end of the drive, the window

regulator broke, but Rob was able to repair it.

Back

in the shop, we continued work on the tire rack, can carrier and

generator mount. In the photo above, the generator will sit in

the "cups" on the top of the can rack.

As a

sanity check, we placed a full sized 395/85R20 tire on the rack to

insure that things were going according to plan. Above, you can

see the can rack and access ladder holding frame. The cables are

used to extract cans from the horizontal rack which holds 3 cans.

The rack on the top holds 3 more cans, but the cans sit vertically.

The

tire fits per the design, so I was pleased. The tire crane mast

was added to the rack as was the crane boom and support stops.

The

old 30 gallon fuel tank was removed and the sending unit was

inspected. Yuck!! Note the crud on the pipes.

The

old 30 gallon tank was replaced with a brand new 58 gallon tank from

ProPower in Windsor, Canada. The dimensions were perfect, so we

were all pleased.

Some

new plumbing was required as was a new sending unit. That was

actually good news as the old unit look nearly unclean-able.

The

new Honda EU3000 generator was placed on the rack as a sanity

check. Once the fit was confirmed, tie down straps were

fabricated to insure that the generator stays put when wheeling.

The

old fuel tank mounts needed to be extended to handle the extra width of

the new, high-capacity tank. Rob used his hand-held band saw to

cut the old frame.

The

existing ends of the frame were extended using thick-wall 2x2" steel

tubing. Straps were welded on top to insure that the height of

the rails were constant for the entire length.

The

final rack was painted, the boom was added and the tire lift winch was

installed. We stayed up until midnight painting the frame to hold

our schedule.

The

finished tire rack was carefully lifted aboard the truck. Above,

Rob's buddy Kelly helps out.

This

was a tight fit and some careful forklift driving was required to get

the rack in place.

Once

the rack was in place and bolted down, the generator was installed into

the mounting cups and the tie down straps were installed.

The

finished truck, ready for a run to the hardware store for parts.

The tire rack is hidden in the shadow of the camper. Note that

the area under the camper will be completed in San Diego. That

area will have a number of tool boxes and storage compartments.

In addition, the propane rack will be fabricated and installed.

A

front-on view of the truck.

The

driver's side view shows the generator mounting.

Kathleen shot this as I headed out to the Big R store for supplies.

This was a ton of work. Actually, it was more work than I expected but persistence prevailed in the end. Rob proved himself an expert fabricator and did an outstanding job on all facets of the work. Our work here in La Junta is complete and tomorrow we will load both trucks and return to San Diego to complete internal actions and an electrical retro-fit.

Many thanks to Rob

and Erin for hosting us and allowing us to use the shower and laundry

facilities at their home.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2010, all rights

reserved.

For your enjoyment only, not for commercial use.