We

decide that we wanted to head south to the coast but we were a

bit burned out from the long drive the previous day. We

got a really late start and then finally decided that we would

visit the Jameson Distillery in Midleton. So, we piled into

the car and headed out. The day was perfect with bright

sun and mild temperatures. The scenery was great in the

full sun.

The photos below are what we saw.

We got

to Midleton and headed out on foot. The town was actually

quite busy with traffic, mostly tourists like us. We found

a a place

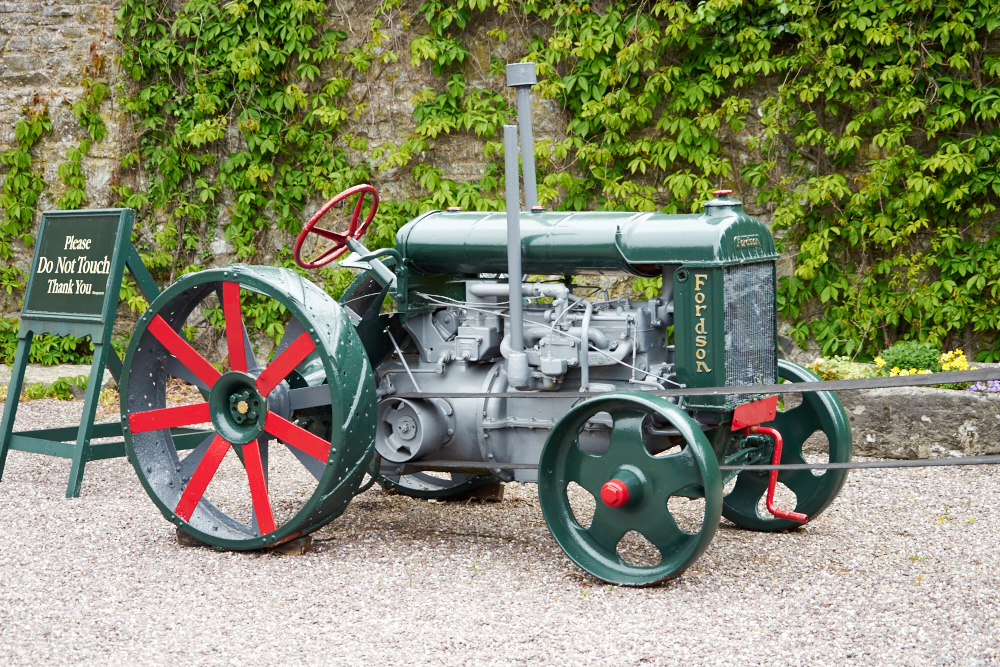

As we

entered the distillery, they had some nice artifacts on

display. This is, of course, fake but it still looks cool.

This

copper pot is from one of the boiler areas.

The

barley malting house is a big building made of stone.

I love

the stonework in their buildings here. The corners are cut

stone, the balance is raw stone.

An old

belt-powered piece of farm equipment.

Interesting

that the name of the tractor is Fordson. This is the way

it was done in the old days.

The tour

was reasonably informative; we got the download on the brewing

and distilling process. And there was some nice old

equipment on display.

This

belt-powered piece of equipment is likely a crusher or

grinder. Note the large flywheel on the right.

The back

side of the malting house. 5 stories of stone walls held

together by steel bars with cast iron plates. These were

used to support the walls.

The barley

was ground into grist in the mill. The mill was powered by

water that was carried by a small canal called a "race".

The race carried the water to the water wheel.

The

water was scooped by the flutes in the wheel causing it to

turn. This wheel has provide the motive power for the mill

since day one. It was only decommissioned about 10 years

ago.

The

wheel does not turn fast, but it DOES turn.

One of

the millstones that was used for the grinding the grist.

One of the

old distillery delivery trucks.

This was

an interesting old tractor used at the plant. The

manufacturer, Scammell, has long gone out of business, but a web

search will bring up some interesting photos of older trucks.

One of

the old copper stills used as part of a 3-still process.

These

stills were some of the largest in the world during their day.

A large

amount of heat was required to heat the stills which required

appropriate stacks to clear the smoke. Anthracite coal was

used "back in the day".

Many of

the buildings on the site were quite large.

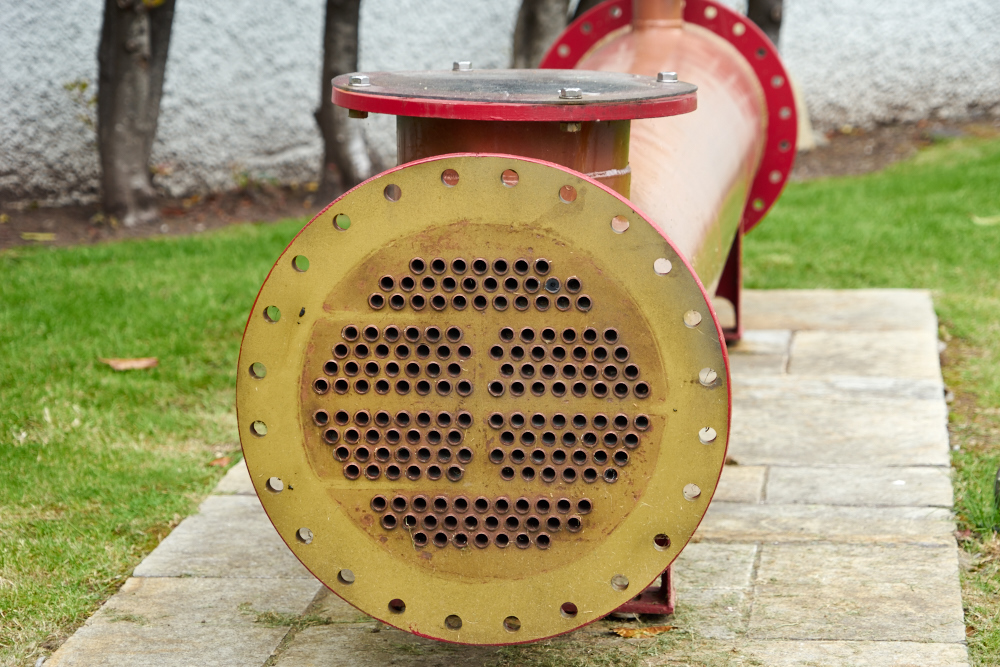

A modern

day condenser. Why this is not in service is a

question. I am sure they are expensive to fabricate.

The last

stop on the tour was the tasting room.

The Jameson tour was interesting and very worthwhile. And not just for the free liquor. If you are in the area, it is worth stopping in. The tour takes about 90 minutes, plus the tasting. Jameson distills many brands of liquor, including my (current) favorite Red Breast. Some of their brands are quite pricey. I must say, however, that I tried Jameson 12 year and it was, at the time, better than Red Breast.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2015, all rights

reserved.

For your enjoyment only, not for commercial use.