We left

Dublin in our new rental car with Steve at the wheel. We

traveled south to Waterford and then north to Glash Farmhouse,

our residence for the next few days.

The photos below are what we saw.

Coming

into Waterford we spotted this modern suspension bridge.

Our

route never took us close enough to get a clear shot of the

bridge; this was the best I could do from the back seat of the

car.

Waterford

had a big church steeple in the center of town.

We

stopped for lunch at a small pub near the Waterford Crystal Factory.

After we finished lunch, we decided to take their tour.

The tour was clearly a shill for the gift shop, but we did learn

some interesting fact.

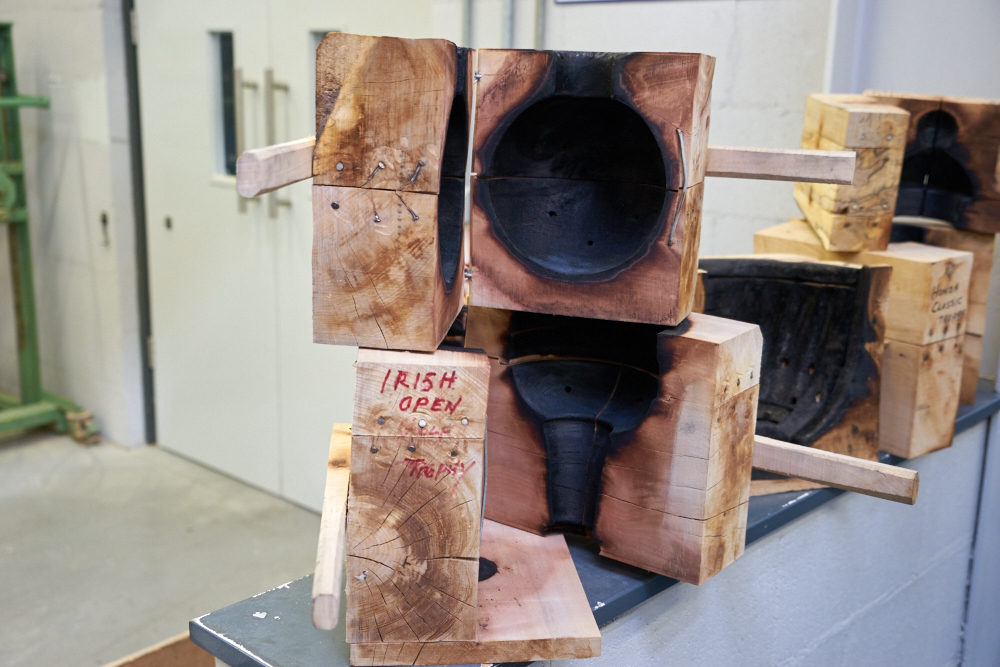

Interestingly

they still use wooden molds for their specialty items and

one-off trophies.

The

molds can be use a few times before the heat of the molten glass

damage them beyond further use.

The new

molds are made in their mold shop out of Irish beechwood.

The

molds are damaged with each use, but they are usually only used

once.

A large

portion of the actions done at the factory are manual.

Above, this fellow has removed glass from the furnace and is

preparing to blow it through the long pipe.

The

glass is spun on the pipe and shaped with a heat-proof pad while

being rolled.

This

piece was completed and is now cooling.

The

glass is blown while being spun to maintain symmetry.

The

now-bigger piece is dropped into a shaping mold.

He

continues to blow, forcing the bottom of the glass into the

shape of the mold.

The mold

is the cast iron container below. Note that the blow pipe

has a funnel-shaped end to hold the glass.

He

continues to work the glass while it is still pliable.

The

piece is separated from the blowpipe and is being returned to

the kiln to anneal and re-heat for additional forming.

A

different piece is fresh out of the furnace and is being shaped

while being spun.

The

rotation while blowing insures symmetry.

Once the

pieces have fully cooled they are moved on to the cutting

stations. Craftsmen make each cut by hand using diamond

blades.

Note the

guide lines to assist in the cutting.

The

really complex patterns that have curves are done by a

robot. The robot has a shape measuring tool and first

measures the outline of the piece to account for any

eccentricities. Then the cutting tool is rotated into

position and the cutting begins using water as the coolant.

The

cutting scars the glass and leaves it with a milky finish.

To restore the bright clear luster, the pieces are bathed in a

combination of hydroflouric and sulpheric acids. The

hydroflouric acid eats away the surface of the glass.

On some

pieces, the milky color from the cutting process is desired.

Here a copper wheel

coated with diamond dust is used to produce the surface

abrasion patterns.

This trophy is hand

crafted and made of a number of components that have been

attached to one another.

Like every other

tour, it ends in the gift shop. But, they had some very

nice stuff.

From Waterford, we

headed north toward our destination at Glasha. Along the

road we spotted an old watchtower that has fallen into disrepair.

We arrived a the Glasha Farmhouse around sundown and had to

hustle into the nearest town to find some food before the

restaurants closed.

A big portion of our trip was along Ireland's equivalent of an American freeway. There was plenty to see, but at some level all freeways look alike independent of what country they are in. Waterford is worth a visit if you are in the area, but I am not sure I could suggest it as a destination. The crystal factory is worth a stop if you happen to be in Waterford. They make nice products, albeit quite pricey.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2015, all rights

reserved.

For your enjoyment only, not for commercial use.